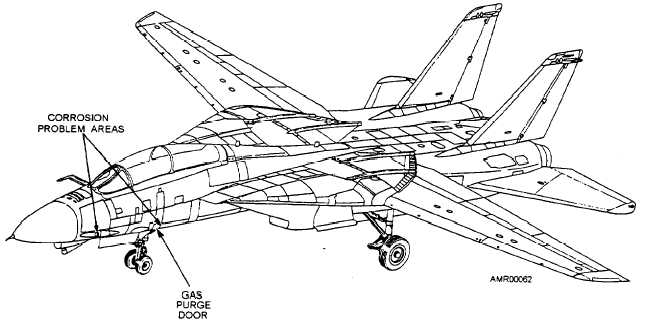

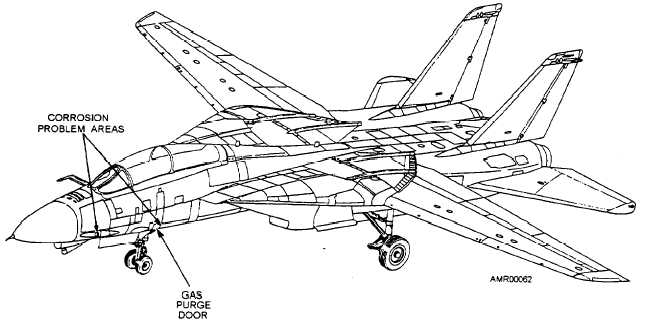

Figure 4-24.—Gun blast area corrosion points.

preservative coatings are not used on jet aircraft

landing gear wheels. During inspections, maintenance

personnel should pay particular attention to the

following areas:

Magnesium wheels, especially around bolt

heads, lugs, and wheel well areas

Exposed metal tubing, especially at nuts and

ferrules, and under clamps and identification

tapes

Exposed connectors, such as indicator switches

and other electrical equipment

Crevices between stiffeners, ribs, and lower skin

surfaces, which are typical water and debris traps

Water Entrapment Areas

Aircraft have drains installed in areas where water

may collect. However, these drains may not be

effective either because of improper location or

because they are plugged by sealants, fasteners, dirt,

grease, and debris. Daily inspection of drains is a

standard requirement, especially aboard ship.

Q57. Cockpit fasteners should be touched up with

what color paint?

Q58. In water entrapment areas of an aircraft, drains

are required to be inspected how often?

Wing Fold, Flap, and Speed

Brake Recesses

Flap and speed brake recesses are potential

corrosion problem areas because they are normally

closed when on the ground. Dirt and water may collect

and go unnoticed. Wing fold areas contain

complicated shapes and assemblies that are difficult to

cover with a protective paint coating or preservative

film; thus, corrosion is present. Wing fold areas are

extra vulnerable to salt spray when wings are folded

aboard ship. To thoroughly inspect this area,

maintenance personnel should use a mirror to check

the back sides of tubing and fittings. Also, they should

pay particular attention to aluminum alloy, wing lock

fittings (such as those used in some current aircraft

models).

External Skin Areas

Most external aircraft surfaces are ordinarily

covered with protective paint coatings and are readily

visible or available for inspection and maintenance.

Even here, certain types of configurations or

combinations of materials can cause trouble under

shipboard operating conditions and require special

attention.

Magnesium skin, when painted over, is not visibly

different from any other painted metal surface.

Magnesium surfaces are identified in the applicable

structural repair manual. When an aircraft contains

4-33