A yellow-colored sealing ring is pressed on each end

of the munition as a seal between the munition and the

tube body. This prevents gas pressure from escaping

during ejection. A green-colored arming cap is installed

on the timer end of a flare or on the rotochute end of a

sonobuoy. The green arming cap lanyard is connected

to the timer knob of the flare, and then pressed on over

the flange of the sealing ring. When you install an

arming cap on the sonobuoy, the lanyard is not used.

Mount a white cross-shaped plastic spacer on the aft

sealing ring of the forward munition. This provides

enough space between the forward and aft munition to

provide an expansion chamber for ejecting the aft

munition.

After you have installed the adapter, install the

munitions in the dispenser tube.

When a SUU-25F/A dispenser is fully loaded and

uploaded on the aircraft, the pilot may eject flares. The

pilot must first select the weapons control system, and

then trigger the dispensing switch. A 28-volt dc

electrical signal passes through an electrical cable from

the aircraft to either receptacle J1 or J2 of the dispenser.

The signal is routed from the dispenser receptacle to the

stepper switch, causing the stepper switch to step from

the preset ARM position to the No. 1 position. This fires

the No. 1 impulse cartridge. The gas pressure, generated

by the fired cartridge, is ported through a gas tube,

internally along the side of the dispenser, into the aft

expansion chamber ahead of the aft flare.

As the gas pressure increases, the aft retaining lock

shear pin is cut, allowing the aft flare to eject. As the

timer end of the flare approaches the rear of the tube,

the arming finger of the arming mechanism engages the

yellow sealing ring. The sealing ring cams the arming

finger down, which, in turn, cams the arming hook up

to engage the green arming cap. This action allows the

flare to extend the lanyard. The lanyard extracts the

timer knob and arms or starts the flare functioning

sequence.

When the pilot triggers the system again, the stepper

switch steps to the No. 2 position and fires the cartridge.

This meters the gas pressure directly into the forward

expansion chamber. As the gas pressure increases, the

forward retaining lock shear pin is cut. This allows the

forward flare to be dispensed in the same manner as the

aft flare. If the aft flare failed to eject, the gas pressure

generated for ejecting the forward flare produces

sufficient gas pressure to purge both flares out of the

tube.

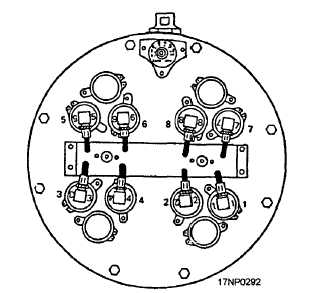

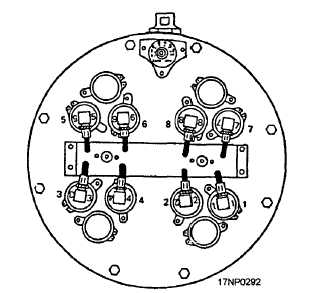

The procedure for the remaining three tubes is the

same. The firing sequence of the breeches is stamped

into the metal of the breech caps, as shown in figure

10-35.

Maintenance Requirements

Organizational-level maintenance is limited to a

visual inspection of the dispenser. You need to look for

damage, such as cracks or breaks in the aft retaining

locks or suspension lugs, unburned pellets or obstructors

in the breech sleeve, and frayed or broken breech leads.

For further information concerning the SUU-25F/A

dispenser, you should refer to Dispenser SUU-25F/A,

NAVAIR 11-75AA-48.

Q1.

Q2.

.

Q3.

Q4.

Q5.

REVIEW NUMBER 5

What is the maximum number of parachute

flares you can load in the SUU-44 flare

dispenser?

How many size A sonobuoys can be launched

from SUU-25F/A dispensers?

What impulse cartridge is used to fire the

SUU-25F/A impulse cartridge?

The impulse cartridge is fired by what voltage?

When performing organizational-level

maintenance on the SUU-25F/A, you should

look for what types of damage ?

Figure 10-35.—Breech cap identification numbers.

10-31