The transmitter contains a high-voltage power

supply, modulator control circuitry, the modulator,

and the magnetron RF output stage. Output pulses

and transmitter output frequencies are generated in

the transmitter. The magnetron output RF is

waveguide coupled to the antenna for propagation.

The transmitter consists of the necessary

components to accept the synchronization signals

from the APP and generate an output pulse. This

pulse is then fed into the waveguide system and

radiated out of the antenna. The transmitter system is

conventional except for the frequency agile mag-

netron. The magnetron is mechanically modulated at

75 Hz to vary the output pulse frequency over a

60 MHz (nominal) range. This is accomplished with

a motor-driven tuner that physically changes the

interior characteristics of the magnetron. This agility

enhances the clutter elimination capabilities of the

system, and it is an option available to the operator.

The basic transmitter characteristics are as

follows:

Frequency:

Peak Power:

PRF:

Agility:

The receiver

local oscillator,

8.5 to 9.6 GHz, manually tunable

143 kW minimum

1600 Hz, line locked with

0.5 microsecond pulsewidth

(short pulse)

60 MHz nominal, 40 MHz

minimum

system includes an AFC-controlled

IF amplifiers, video detecting and

them to the APP for subsequent distribution and

display. A solid-state, frequency-agile AFC system

allows continuous tuning of the receiver local

oscillator to track the transmitter and provide a

60-MHz IF amplifier input. The receiver agile

modulator-demodulator generates the synchroni-

zation, which locks the transmitter and the receiver

AFC together.

The waveguide pressurization system consists of

an air pump and a replaceable, air-drying desiccant

cartridge. The pump furnishes dry pressurized air for

the waveguides between the RT and the antenna. This

pressurized air prevents arcing in the waveguide when

the aircraft is flying at high altitudes.

The BITE circuits perform continuous monitoring

of vital functions within the RT. The fault isolation

meter and switch provide a means of monitoring

selected functions to aid the technician in the removal

and replacement of faulty components.

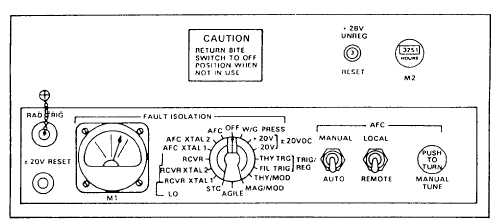

Figure 3-4 shows the controls on the

RT-889/APS-115. There is a fault isolation switch

and meter for checking the operation of the

receiver-transmitter. The AFC section allows the

operator to select the AFC required. There is also an

elapsed time meter and two power reset circuit

breakers.

CAUTION

Return fault isolation switch to the OFF

processing circuits, range mark generating circuit,

position during normal operation. Failure

and BITE circuitry. The receiver processes received

to do so will result in improper operation of

echo pulses, converts them to video, and delivers

the system.

Figure 3-4.-RT-889/APS-115 receiver-transmitter control panel.

3-4