1,000-foot counter and then add the 100-foot pointer

indication.

CAUTION

It is possible to misinterpret the counter-

pointer altimeter by 1,000 feet immediately

before or after the 1,000-foot counter

moves. This error is possible because the

1,000-foot counter changes when the

foot-pointer is between the 900- and

1,000-foot position.

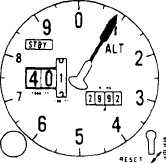

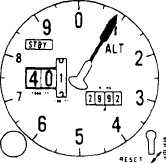

Counter-Drum-Pointer Altimeter.— The only

real difference between this altimeter and the

counter-pointer altimeter is the addition of a 100-foot

drum (fig. 2-9). This drum follows the 100-foot

pointer, and it is this drum that actuates the

1,000-foot counter. In this way it prevents the

reading error when the 1,000-foot counter switches.

There are two methods of reading the indicated

pressure altitude.

One way is to read the

counter-drum window without referring to the

100-foot pointer. This will give a direct readout of

both thousands and hundreds of feet. The second way

is to read the counter window and then add the

100-foot pointer indication. The pointer serves as a

precise readout of values less than 100 feet.

This sample altimeter has a servoed mode and a

pressure mode of operation. The mode of operation is

controlled by a spring-loaded, self-centering mode

switch, placarded RESET and STBY. In the servoed

mode, the altimeter displays altitude, corrected for

position error, from the synchro output of the air data

computer. In the standby mode, the altimeter operates

as a standard altimeter. In this mode, it uses static

Figure 2-9.-Counter-drum-pointer altimeter.

pressure from the static system that is uncorrected for

position error.

The servoed mode is selected by placing the mode

switch to RESET for 3 seconds. The ac power must

be on. During standby operation, a red STBY flag

appears on the dial face. The altimeter automatically

switches to standby operation during an electrical

power loss or when the altimeter or altitude computer

fails. The standby operation is selected by placing the

mode switch to STBY. An ac-powered internal

vibrator automatically energizes in the standby mode

to lessen friction in the display mechanism.

PRESSURE ALTIMETER ERRORS.— There

are five categories of errors relating to pressure

altimeters. They are the mechanical error, the scale

error, installation/position error, reversal error, and

hysteresis error.

Mechanical Error.— Mechanical error is caused

by misalignments in gears and levers that transmit the

aneroid cell expansion and contraction to the pointers

of the altimeter. This error is not constant, and it must

be checked before each flight by the setting

procedure.

Scale Error.— Scale error is caused by irregular

expansion of the aneroid cells. It is recorded on a

scale correction card maintained for each altimeter in

the instrument maintenance shop.

Installation/Position Error.— Installation/

position error is caused by the airflow around the

static ports. This error varies with the type of aircraft,

airspeed, and altitude. The magnitude and direction

of this error can be determined by referring to the

performance data section in the aircraft NATOPS

manual.

An altimeter correction card is installed in some

aircraft that combines the installation/position and the

scale errors. This card shows the amount of correction

needed at different altitudes and airspeeds.

Reversal Error.— Reversal error is caused by

inducing false static pressure into the system. This

normally occurs during abrupt or huge pitch changes.

This error appears on the altimeter as a momentary

indication in the opposite direction.

Hysteresis Error.— Hysteresis error is a lag in

altitude indication due to the elastic properties of the

material within the altimeter. This occurs after an

aircraft has maintained a constant altitude for an

extended period of time and then makes a large, rapid

altitude change.

After a rapid descent, altimeter

2-9