Gearbox Assembly

SSPU Turbine Engine

The external gearbox assembly provides for two of

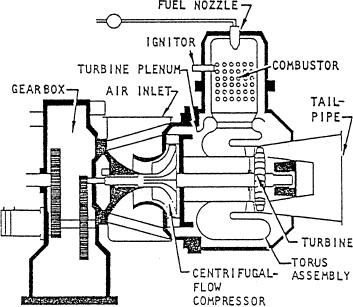

The SSPU turbine engine is composed of four major

the SSPU's mount pads and the mounting area for the

parts: (1) a 2-stage centrifugal-flow compressor, (2) a

SSPU'S power section. The internal gearbox assembly

3-stage axial-flow turbine, (3) an inlet plenum assembly,

contains the reduction gearing that enables the power

and (4) a combustion system. Figure 7-31 is a cutaway

section to drive the supporting accessories and the

view of an SSPU turbine engine showing the relative

loading components at the proper speed. When the

position of each of these components.

power section is operating at 100 percent speed (41,730

The compressor impellers and three turbine wheels

rpm), the unit's gears provide the following output

are locked together by means of curvic couplings. A tie

speeds:

bolt through the center of the wheels makes this

8,000 rpm

assembly a single rotating unit. A floating ring journal

bearing and seal assembly on each end of the shaft

Load compressor

8,000 rpm

support this rotating unit.

Hydraulic pumps

3,600 rpm

Outside air is drawn into the compressor through the

inlet plenum into the combustor where it is mixed with

Lubrication System

fuel. The fuelhir mixture is ignited by the igniter plug

at 10 percent of engine speed. When the unit reaches 95

The SSPU lubrication system provides lubrication

p e r c e n t of engine speed, the ignition system is

for the engine and gearbox assembly, load compressor,

a u t o m a t i c a l l y de-energized because at this point

and generator. It is a full pressure, wet sump system

combustion is self-sustained. The hot gases pass from

consisting of the oil pump assembly, oil falter assembly,

the combustion chamber into the torus assembly. The

oil pressure regulator, and a check valve. The system is

torus assembly directs the hot gases onto the three

also equipped with pressure and temperature switches

turbine wheels. By imparting energy to the turbine

and a temperature sensor for readouts on the PHM

wheels, the hot gases cause them to rotate and provide

indicators. The oil sump is an integral part of the SSPU

shaft power for operation of the compressor, gearbox

assembly. The oil sump has a capacity of 8 gallons and

assembly, and driven equipment. The spent gases are

is equipped with a drain fitting, a dip stick, and a sight

expelled through the tail pipe into the PHM exhaust

glass for monitoring oil quantity. The SSPU lubrication

duct.

system is serviced through a filler cap. The filler cap

should be removed only when the SSPU is shut down.

The oil level should be checked daily.

Fuel System

The SSPU fuel system automatically regulates fuel

f l o w to maintain constant engine speed and safe

operating temperatures under varying conditions of

starting, acceleration, and load application. If the fuel

supply pressure decreases to 4 psig, a LOW FUEL

PRESSURE indicator on the EOS panel will illuminate.

Control Panel

The control panel for each SSPU is located in the

EOS. This panel is divided into three sections, as shown

in figure 7-32. The top section provides switches for

SSPU de-icing and engine wash functions. The center

section provides meters to indicate the operating oil

temperature, oil pressure, exhaust gas temperature, and

percent speed of each SSPU engine. Filter assemblies,

Figure 7-31.--Cutaway view showing main components of an

located on the side of the center panel, are used to filter

SSPU turbine engine.

electromagnetic interference (EMI) generated in the

7-34