kVA(180 amperes). It will supply 450-V ac, 3-phase,

entire enclosure is mounted on a steerable, highway

400-Hz power to the PHM at 125 kW continuous duty.

towable, 4-wheel trailer. (See fig. 7-36.)

The motor generator is a brushless, two-bearing,

TROUBLESHOOTING

PROCEDURES

salient-pole unit. The unit is self-ventilated. The rotating

brushless system consists of the salient-pole motor and

In troubleshooting the PHMs electrical system, you

generator rotor assemblies, fan assembly, rotating

should first use the fault or out-of-tolerance indications

rectifier assembly and exciter armature assembly, all

displayed on the electrical system control panel. You

mounted on a common shaft and dynamically balanced.

should then locate the associated fault directory and

fault trees in the appropriate technical manuals.

The voltage regulator unit is a completely static,

modular unit. It is provided with a plug-in connector for

Use the panel indications and the appropriate

ease of removal and replacement. The regulator contains

guidelines in the technical manuals to analyze the

plug-in circuit modules for 3-phase voltage sensing,

symptoms of the trouble, isolate them to a probable

exciter field control, over/undervoltage monitoring, and

cause, and recommend corrective procedures to return

underfrequency monitoring.

the system to its operational condition. The information

you can derive from the panel indications, the technical

The control panel is hinged for easy access and

manuals, and the electrical power system one-line

provided with a weatherproof shield to prevent direct

diagram should provide you with the information you

rainfall on the panel during operation of the controls or

will need to perform basic fault isolation procedures.

observation of the instruments.

In the preceding sections, you read about the main

The shore power transformer is a 3-phase,

propulsion, power train, control, and electrical systems

single-core, isolating type. It takes power from the

of the PHM. In the following section, we will take a look

power unit input terminals and provides two isolated,

at the auxiliary systems, their components, and the

ungrounded output circuits. The shore power system is

relationship of these systems to the engineering plant.

provided with both input and output circuit breakers,

instruments, and indicators.

AUXILIARY SYSTEMS

T h e mobile electric power unit is capable of

The auxiliary systems of the PHM include the

continuous duty. It can maintain the electrical and

following systems:

physical performance characteristics required for the

Fuel system

PHM under specified input and environmental

conditions. The unit operates on a 480-V ac, 3-phase,

Hydraulic power system

60-Hz power source with a continuous rating of 150

Compressed air system

Seawater system

Bilge drainage system

Let's take a closer look at each of these systems and

how they interface with the engineering plant.

FUEL SYSTEM

The PHM fuel system delivers diesel fuel, marine

(DFM) or JP5 to the hullborne propulsion diesel

engines, to the foilborne propulsion GTE, and to the

SSPUs. The fuel is supplied from dockside or tender

sources through the main deck port or starboard fuel

replenishment fill stations. It is piped to four integral

hull tanks at a rate of 250 gpm without spill or tank

overpressure. From the tanks, the fuel is distributed to

the engines or SSPUs through a cross-feed piping and

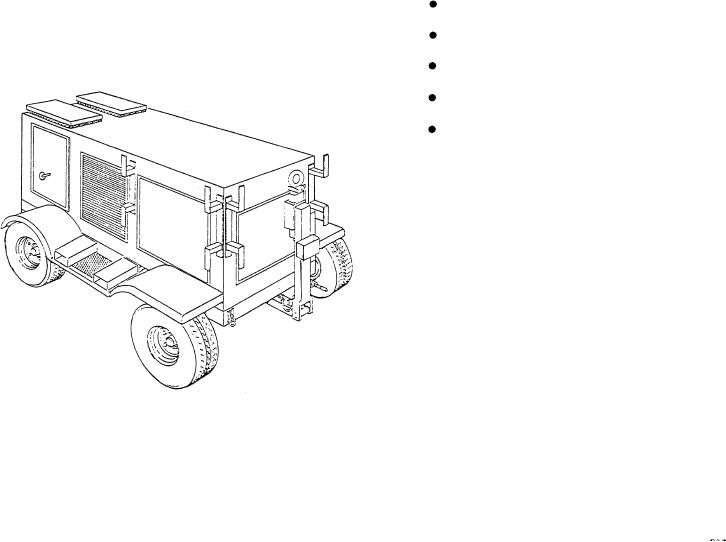

Figure 7-36.--Mobile electric power plant.

controls system. The distribution system is serviced by

7-38