When a machine's vibration signature changes under its

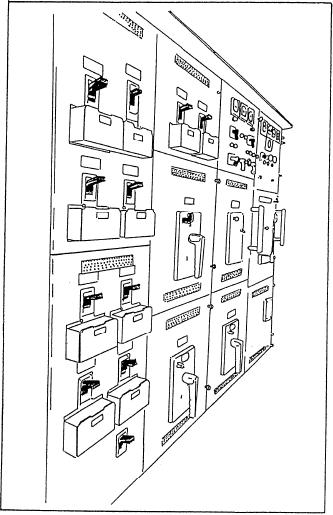

SWITCHBOARDS

standard operating conditions, an impending defect is

Distribution of the electrical power generated by a

starting to change the machine's mechanical condition.

ship's service gas turbine generator (SSGTG) or a ship's

Different defects will cause the vibration signature to

service diesel generator (SSDG) is accomplished by the

change in different ways. Analyzing these data will

switchboards. The operation and maintenance of the

provide a means of determining the source of the problem

60-Hz switchboards on all gas turbine-powered ships

as well as a warning of the problem itself.

are similar, though they will, of course, consist of some

items unique to a particular class of ship.

SAFETY AND HANDLING PROCEDURES

Construction

When it becomes necessary to disassemble and

Switchboards are constructed to withstand

reassemble a motor or generator, follow the procedure

high-impact shocks. Switchboard units consist of a

outlined in the manufacturer's technical manual. Use the

sturdy box frame built of angles and other structural

greatest care when handling the machines to prevent

shapes. This design provides enough strength for the

damage to any part. Remember, careless handling of

unit to resist breakage and distortion resulting from

parts will often cause more damage to a machine during

shock. It also provides enough stiffness to prevent

d i s a s s e m b l y or reassembly than the machine will

excessive vibration.

receive in years of general use.

All switchboards on gas turbine-powered ships are

All rotating elements of motors and generators are

of the dead-front construction. This means the

carefully balanced in the manufacturer's plant before

s w i t c h b o a r d units are protected by a sheet metal

assembly. This reduces noise, vibration, and wear of

enclosure. Figure 5-29 is an example of a dead-front

collector rings and brushes. It also improves the overall

electrical and mechanical performance of the machine.

The balance tends to become worse during normal

service because of vibration and shock. To maintain

optimum performance, remember to handle the rotating

parts carefully during disassembly and assembly.

ELECTRIC PLANT CONTROL SYSTEM

MAINTENANCE

As you advance in the GS rating, your

r e s p o n s i b i l i t i e s for the maintenance, repair, and

operation of the electric plant control system will

increase. Your assigned tasks will include

t r o u b l e s h o o t i n g and repairing motor controllers,

motors, power panels, lighting circuits, and distribution

switchboards. It may appear that most of these tasks

would belong to the EM. However, on most gas turbine

ships, most of the electrical and electronic equipment

and systems in the main engine rooms and the generator

room is the responsibility of the GSEs.

The information in this section will provide you

with a basic knowledge of 60-hertz (Hz) switchboards,

t r a n s f o r m e r s , voltage regulators, and water wash

systems. After reading this section, you should be able

to identify basic maintenance procedures involved with

Figure 5-29.Dead front of a ship's service switchboard.

these components.

5-33