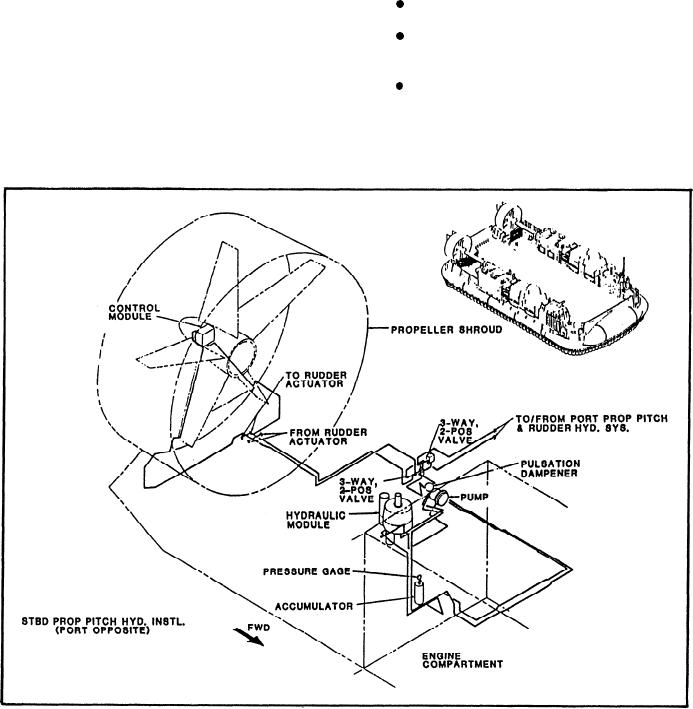

The propeller pitch control system is composed of

a secondary CSEP channel maybe selected by using the

command and control keyboard. The control voltage

the yoke assembly, propeller pitch indicator, a control

supplied to the propeller pitch control has a positive to

u n i t , pitch levers, potentiometers, and amplifiers.

negative voltage range.

Pushing the yoke in or pulling it out will cause electrical

signals to be sent to the electrohydraulic servo valve and

actuator, which permits the operator to control the pitch

TROUBLESHOOTING CRP/CPP SYSTEMS

of the propellers. (Refer to fig. 5-27). An indicator at the

operator station provides an indication of propeller

For a GSE, familiarity with normal gauge readings

pitch.

and maneuvering times under varying conditions is

Electrical control signals for the propeller pitch

essential to troubleshooting electrohydraulic control

systems. Normal operating pressures will vary along

by moving the yoke in and out. The propeller pitch

with the following conditions:

levers set the center point for the plus and minus, in and

Changes in shaft speed

out, movement of the yoke. Inward movement causes a

p i t c h increase; outward movement causes a pitch

At every position change throughout the

decrease. Placing the propeller V PITCH switch in the

pitch-changing stroke

OFF position takes the yoke out of the propeller pitch

Between shaft sets because of manufacturing

control system. Propeller pitch is then controlled by the

tolerances

propeller pitch levers. The propeller pitch signals are

sent through the control systems electronic package

As an operator or maintenance technician, you

should avoid making any variations from these norms.

(CSEP) to the propeller. If a CSEP malfunction occurs,

Figure 5-27.--LCAC propeller pitch control system.

5-28