cushion (LCAC) vessels. The purpose of CRP/CPP

system is to provide the ahead and astern propulsion

thrust for a ship by changing the pitch of the propeller

blades.

The operation, maintenance, and repair of the CRP,

C P P , and propeller pitch systems are within the

capabilities of ship's personnel. Since these systems

interface electronics with mechanical operations, the

G S E s must work closely with the GSMs when

troubleshooting and repairing these systems.

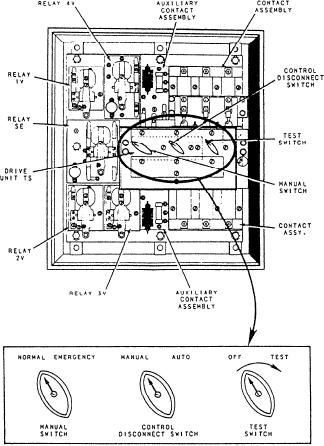

DD-963/DDG-993 CLASS SYSTEM

The pitch of the CRP propellers is established

electrically through two identical electrohydraulic pitch

control systems. One is located in each main engine

room. Each system has two basic parts or groups of

components. These are the CRP electronics enclosure

and the oil distribution (OD) box-mounted components.

T h e OD box-mounted components consist of the

electrohydraulic servo control valve and two slide-type

potentiometers. Figure 5-23 shows the relationship

between the two basic parts of the system. Refer to

Figure 5-22.--Pictorial view of an ABT.

figure 5-23 as you read the following paragraphs.

The procedures you will use to troubleshoot the

As a good maintenance technician, you should try

t o localize the problem by following the basic

electrohydraulic servo control valve are the same as

troubleshooting steps. In troubleshooting the ABT, you

those we discussed for troubleshooting solenoids. The

should first make certain that both power sources are

servo valve consists of a two-coil solenoid. Each coil

available to the ABT. If both sources are available, you

has a dc resistance of about 1000 ohms. Check this with

will then have to de-energize both sources of power and

an ohmmeter. The total resistance of the solenoid should

tag the ABT out of service. First check the mechanical

read 500 ohms when you measure it from the two

o p e r a t i o n of the ABT, then make an electrical

conductors that run between the electronic enclosure

examination. After you locate the faulty part, remove it

and the terminal box.

and replace it. Your final step in troubleshooting the

The linear feedback and shaped potentiometers

ABT is testing the effectiveness of your repair.

(LINEAR POT and SHAPED POT in fig. 5-23) are

These troubleshooting steps are general in nature.

mounted side by side on the top of the OD box. Each

Always use the manufacturer's technical manual and the

potentiometer is housed in a rectangular box about 18

appropriate troubleshooting charts whenever you are

inches long, 1 1/2 inches wide, and 1 1/2 inches tall. A

repairing or replacing components of MBTs and ABTs.

shaft that moves the sliding contact extends out of the

forward end of each potentiometer box. A Y-shaped

ELECTROHYDRAULIC CONTROL

yoke connects the ends of the potentiometer that extend

SYSTEMS MAINTENANCE

out the forward end of the OD box. The follow-up rod

provides a mechanical positioning of the potentiometer

An electrohydraulic control system is one that uses

s h a f t s that corresponds to actual propeller pitch

electrical or electronic signals and components to

positions. The follow-up rod also positions a mechanical

control the flow of oil or hydraulic fluids. On gas

pointer along a calibrated scale mounted between the

turbine-powered ships, the most important

potentiometers. Slots in the potentiometer mounting feet

electrohydraulic control system is the controllable

provide for longitudinal position adjustments when you

reversible pitch (CRP) propeller or controllable pitch

propeller (CPP) system. This system is called the

are calibrating the zero pitch feedback and readout

propeller pitch control system on the landing craft, air

signals.

5-23