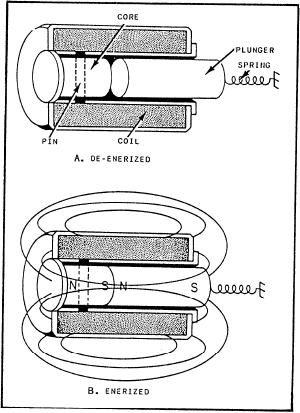

of the plunger in view A when the coil is de-energized.

solenoid-operated valves also contain microswitches to

Compare view A with view B, which shows the plunger

s h o w the valve's position. The console operator

position when the coil is energized. When current flows

depresses a pushbutton to cycle the valve to a new

through the conductor, it produces a magnetic field. The

position. This signal is sent to the solenoid of the valve.

m a g n e t i c flux produced by the coil results in

Depending on the signal received, the solenoid cycles

establishing north and south poles in both the core and

the valve to the requested position. An actuating rod in

the plunger. (See view B.) The plunger is attracted along

the valve rotates or slides, depressing a microswitch.

the lines of force to a position at the center of the coil.

The signal from the microswitch is sent backup to the

As shown in view A of figure 5-20, the de-energized

console, indicating the valve's position.

position of the plunger is partially out of the coil due to

T h e maintenance on solenoid-operated valves

the action of the spring. When voltage is applied, the

includes inspecting, cleaning, testing, and

current through the coil draws the plunger within the

troubleshooting the solenoid and the microswitches.

coil, resulting in mechanical motion. When the coil is

The procedures used to maintain and troubleshoot

de-energized, the plunger returns to its normal position

microswitches were discussed earlier in this chapter. We

because of spring action. The effective strength of the

will now briefly describe the maintenance procedures

magnetic field on the plunger varies according to the

associated with solenoids.

distance between the plunger and the core.

To properly troubleshoot a solenoid, you must first

know how it is constructed and how it works. Figure

Maintenance of Solenoids

5-20 is a cutaway view of a solenoid showing the

solenoid action. A solenoid is an electromagnet formed

If you suspect that a solenoid is not working

by a conductor wound in a series of loops in the shape

properly, your first step in troubleshooting is a good

of a spiral. Inserted within this coil is a soft-iron core

visual inspection. Check the connections for poor

and a movable plunger. The soft-iron core is pinned or

soldering, loose connections, or broken wires. Check the

held in an immovable position. The movable plunger

plunger for cleanliness, binding, mechanical failure, and

(also soft iron) is held away from the core by a spring

improper alignment. Check the mechanism to which the

when the solenoid is de-energized. Notice the position

solenoid is connected (actuates) for proper operation.

Your second step is to check the energizing voltage

with a voltmeter. If the voltage is too low, the result is

less current flowing through the coil and a weak

magnetic field. A weak magnetic field can result in slow

or poor operation. Low voltage could also result in

chatter or no operation at all. If the energizing voltage

is too high, it could damage the solenoid by causing

overheating or arcing. In either case, you should reset

the voltage to the proper value so that further damage or

failure of the solenoid will not result.

Next, check the solenoid coil with an ohmmeter for

opens or shorts, and the proper resistance. If the solenoid

coil is open, current cannot flow through it and the

magnetic field is lost. A short results in fewer turns and

higher current in the coil. The net result of a short is a

weak magnetic field. A high-resistance coil will reduce

coil current and also result in a weak magnetic field. A

weak magnetic field will cause less attraction between

the plunger and the core of the coil. This will result in

improper operation similar to that caused by low

voltage. If the coil is open, shorted, or has changed in

resistance, the solenoid should be replaced.

Finally, you should check the solenoid to determine

Figure 5-20.--Solenoid action.

if the coil is shorted to ground. If you find a short to

5-19