Make a tie as follows:

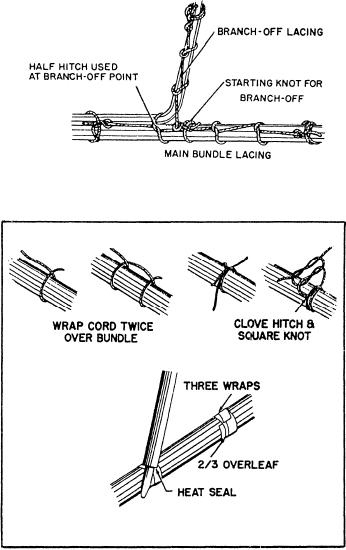

Branch-off Procedure.-- To lace a wire group that

branches off the main wire bundle (fig. 5-15), use the

1. Wrap cord around the wire group or bundle.

following steps:

2. Make a clove hitch, followed by a square knot

1. Start the branch-off lacing with a starting knot

with an extra loop.

located on the main bundle just past the branch-off point.

3 . Trim the free ends of cord to a 3/8-inch

When using single-cord lacing, make the starting knot

minimum.

the same as for regular single-cord lacing. When using

double-cord lacing, use the double-cord lacing starting

Tying Sleeves. When tying sleeves to wire groups

knot.

or bundles, make the ties the same way as you would for

wire groups or bundles.

2. End the lacing with the regular knot used in

single- and double-cord lacing as described earlier.

When it is permitted to use tape, use the following

method:

3. Trim the free ends of the lacing cord to a 3/8-inch

minimum.

1. Wrap the tape around the wire group or bundle

three times with a two-thirds overlap for each turn.

TYING TECHNIQUES. You will use specific

tying techniques for different conditions. Some of these

2. Heat-seal the loose tape end with the side of a

techniques are described in the following sections.

Spacing Ties.-- On the all-wire groups or bundles

Do not use tape for securing wire groups or bundles

that may require frequent maintenance.

where supports are more than 12 inches apart, space ties

12 inches or less apart (fig. 5-16).

Using Cable Straps. Cable straps are adjustable,

self-clinching, lightweight, flat, nylon straps with

molded ribs or serrations on the inside surface to grip

the wire. Use cable straps instead of individual cord ties

for fast securing wire groups or bundles. Cable straps

are available in various sizes and colors to clamp and

identify different sizes of wire groups or bundles.

WIRE WRAPPING

During maintenance and troubleshooting of

engineering control and surveillance system (ECSS)

Figure 5-15.--Lacing a branch-off.

consoles, take notice of the method used to attach the

wires to the backplanes of the consoles. The procedure

used is called wire wrapping. In this section, we will

discuss the principles and techniques involved in this

important procedure.

In simple terms, wire wrapping is the process of

using a series of turns to wrap a single solid wire around

a pin. The equipment on which you would use wire

wrapping have long, square pins or posts at the rear of

the female connectors. The back plane of a console is a

good example of this configuration. The pins are long

enough to allow one to three wires to be wrapped around

them in separate wraps. (A wrap is a single solid wire

wrapped around a pin in a series of turns.) The female

connectors are then connected from pin to pin by a small,

solid-insulated wire, which may or may not be color

coded.

NOTE: Machine-wrapped assemblies usually do

Figure 5-16.--Tying groups of bundles.

not have color-coded wiring. Hand-wrapped assemblies

5-14.