performing this procedure, be careful to ensure that a

troubleshooting, maintenance, and repair of these

components. In this section, we will briefly describe

short wire from one side of the cable being spliced is

connected to a long wire from the other cable. Make

these areas.

certain the sharp ends are then clamped firmly down on

Inspection and Troubleshooting

the conductor. The figure shows a Western Union splice

being staggered.

In the maintenance of cables and connectors, the

first consideration is a thorough visual inspection. This

Fabrication Procedures

check should reveal such defects as corrosion, chafing,

loose connections, broken wires, evidence of

As a GSE, you must learn to fabricate a cable using

overheating, and mismated connectors. You can make

connectors. The type of connector you must use is

additional checks to be sure there are no open or shorted

specified in the service and overhaul instructions for the

conductors in the cable. Usually, you will use an

particular equipment.

ohmmeter to perform these checks.

To fabricate a cable, use the following steps:

1. Disassemble the connector to allow access to the

CAUTION

contacts. Devise a means of holding the connector so

Many ohmmeters are supplied with test leads that

you will have both hands free. (A small bench vise is

are slightly larger than the female sockets used in

useful for this purpose.)

c o n n e c t o r s . Forcibly inserting these probes can

2. Cut the cables to the correct length,

irreparably damage the sockets. Exercise care to prevent

such damage.

3. Strip the wire ends with a wire stripper or knife.

If you use a knife, avoid cutting or nicking the wire

In reference to the caution, most GSEs make pin

strands.

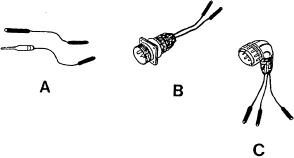

testers. Some examples of pin testers are shown in figure

5-12. A pin tester is a device constructed of the pins and

4. Tin the bare wire ends.

receptacles of cannon plugs (view A). The pin tester can

5. Run the wires through the connector assembly

also be a complete replacement cannon plug that has the

and coupling nuts.

electrical cable attached and the ends of the individual

wires exposed (views B and C). A pin tester can help

6. See that all surfaces are clean.

you prevent short circuits or incorrect readings caused

7 . Flow rosin-core solder into the connector

terminals.

the readings from the cannon plugs. The test leads can

8. Insert each wire into its terminal by holding the

slip off the pin of the cannon plug and short circuit to

tip of the soldering iron against the terminal. As the

the other pins. This could result in serious damage to the

solder melts, push the wire into the cavity, and then hold

cannon plug or the equipment. Make certain you follow

the wire steady while the solder cools.

all applicable electrical safety precautions when using

fabricated pin testers.

CAUTION

Be careful to avoid damaging the connector

insulation with the soldering iron. When you solder the

connector, the recommended sequence is to start from

the bottom connection and work from left to right,

m o v i n g up a row at a time. After soldering the

connections, solder the shields (if used) to a common

terminal on a ferrule. Then lace the cable and reassemble

and moistureproof the connector, if necessary.

INSPECTION, MAINTENANCE, AND

REPAIR PROCEDURES

Figure 5-12.--Fabricated pin testers.

Routine maintenance of electrical connectors and

m u l t i c o n d u c t o r cables involves the inspection,

5-11