off enough insulation to allow the correct number of

turns to be wound around the pin. Then, either place the

end of the wire in a long shallow groove along the barrel

of the wire-wrap tool or insert it into the smaller hole at

the end of the barrel, as shown in view A of figure 5-17.

The groove (or hole) for the wire is carefully sized to

provide the exact amount of tension you will need to

form a secure wrap. Make certain the insulation bottoms

into the wire funnel, as shown in view B. This will allow

you to wrap the correct amount (one to one and a half

turns) of insulated wire around the wrap pin. Anchor the

wire by bending it into the notch in the sleeve, as shown

in view C. Next, slip the center hole at the end of the

barrel down over the pin, as shown in view D. Then

rotate the barrel around the pin. (Depending on the

design of the wire-wrap tool, the barrel will rotate as a

result of finger, hand, or motor action.) The wire should

twist around the pin, as shown in view E. As the wire

twists around the pin, the stripped portion of the wire

that is being held in the groove (or in the other base hole)

will be drawn down to twist and coil around the pin. The

coiling action of the wire on the pin lifts the tool enough

for you to continue the wire coil up the pin, as shown in

views F and G. Your skill is especially important at this

point because too much pressure on the tool will cause

the coils to bunch or overlap. If you are replacing a wire,

carefully run the wire to the next connection and

perform the same procedure on the opposite end. Be sure

you allow enough spare wire for the required number of

wraps on the pin.

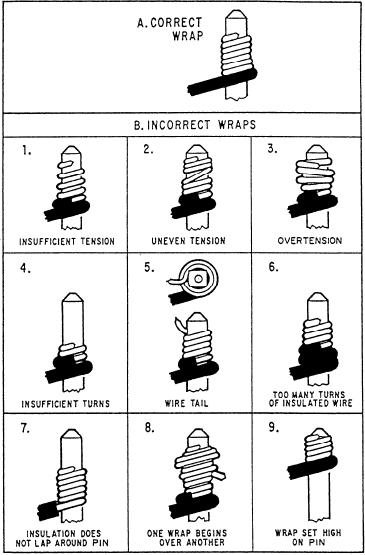

Figure 5-18.--Correct and incorrect wire wraps.

Before actually doing a wire wrap on the item you

are repairing, take time to practice this procedure. Find

a spare connector or spare pin similar to those you will

spaces between adjacent turns. (See fig. 5-18, view B,

repair. Using the same materials required for the actual

sec. 1.)

job, practice a few times. Figure 5-18, view A, shows a

2. Overtension on the wire, resulting in a loose

good wire wrap. It has five to seven and a half snug turns

of wire. Place the insulation about the bottom one or two

connection. You can detect this fault by the turn overlaps

turns with no spacing between adjacent turns, no

and the fact there is not enough surface contact with the

bunching as one turn tries to cover another, and no

pin. (See sec. 3.)

observable nicks in the wire. The number of turns you

will use is based on the wire gauge. Wires and pins with

3. Insufficient number of turns (fewer than five),

larger diameters require fewer turns; those with smaller

resulting in poor contact. (Not enough wire was stripped

diameters require more turns.

first.) (See sec. 4.)

4. Insulation does not extend to the pin, resulting

Avoiding Errors

in increased chances of shorts or wire breaks. (Too much

The following list describes a variety of

wire was stripped.) (See sec. 7.)

I N C O R R E C T wire-wrapping techniques. Some of

5. Reuse of uncoiled wrap. (Each reuse increases

these faults are evident in the numbered sections in view

the likelihood of wire breaks.)

B of figure 5-18.

6 . Attempts to wrap by hand, resulting in

1. Not enough tension on the wire, resulting in a

insufficient and uneven tension and poor contact.

loose connection. You can detect this fault by the open

5-16