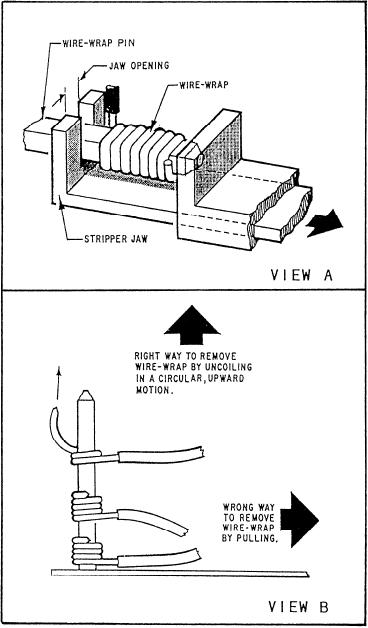

Removing a Wire Wrap

Normally, inner wire wraps are placed near the bottom

of the pin to assure that additional wraps can be added

Normally, you should use a wire-wrap removal tool,

easily. If you have to remove a lower wire wrap, first

as shown in view A of figure 5-19, to remove a wire

remove each wrap above it. Do not remove a wire wrap

by trying to pull it along its axis, as shown in view B.

wrap. This precaution will prevent stress and possible

Remember, each wrap is easily identified because it is

damage to the wire-wrap pin. If you must remove the

formed from the multiple turns of a single solid wire.

wire by hand, however, unwrap the wire without

applying stress to the pin. You can accomplish this by

When removing a wire wrap from a pin, you must

g e n t l y uncoiling the wire with a slight rotating

be careful not to disturb other wraps on the same or

movement over the point of the pin. Make sure that the

adjacent pins or to dislodge the pin. This would cause

manner in which you remove the wire does not cause

poor continuity or an open circuit.

movement of the pin itself, as shown in view B. If a pin

is bent, it will probably break when an effort is made to

ADVANTAGES AND DISADVANTAGES

straighten it. If a pin breaks, first ensure that the broken

length is not left in the wiring to cause possible shorts.

As with any process, certain advantages and

Then take the necessary steps to install a new pin.

disadvantages are associated with wire wrapping. A

good technician can recognize the pros and cons and can

use this knowledge for maintenance and

troubleshooting purposes. A few of the advantages and

disadvantages are discussed in the following sections.

Pros

Some of the advantages associated with wire

wrapping are described in the following list:

1. It is a simplified technique for repairs. (YOU can

just uncoil the wires to remove them and use the proper

simple tool to replace them.)

2. There is no possibility for solder spills. (This

m e a n s you can make repairs without removing

components.)

3. There is no danger of the components

o v e r h e a t i n g . (This is not the case in soldering

processes.)

4. You can perform more in-equipment repairs, and

repair times are faster.

5. There is no danger of burns to ship's personnel.

(This is not the case when hot soldering irons are used.)

6. It provides for durable electrical contact. (The

results are just as good as those achieved with good

soldering techniques, and better than those resulting

from bad soldering.)

Cons

Recognizing the cons of wire wrapping will help

you in some of your troubleshooting efforts. The

Figure 5-19.--Wire-wrap removal procedures.

following list describes some of the cons:

5-17