a voltage reading when the START button is

closed.

4. Place the voltmeter probes at points C and F. A

voltage reading with the START button closed

would indicate a good OL1. It also would

indicate one of the following components is

open: OL3, the main coil, the control fuse, or

the connection to L3.

5. Place the voltmeter probes at points C and G.

Close the START button. A no-voltage reading

would indicate that the trouble is located in the

control circuit to OL3.

The following conditions would indicate a faulty

auxiliary contact: (1) The system operates only as long

as the START button is depressed; and (2) when the

button is released, the system shuts down.

When starting a 3-phase motor, if the motor fails to

start and gives a loud hum, you should stop the motor

by pushing the STOP button. These symptoms usually

mean one of the phases to the motor is not energized.

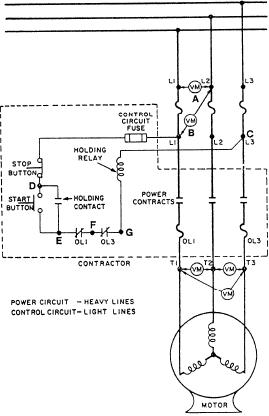

Figure 5-21.--Troubleshooting a 3-phase magnetic controller.

You can assume the control circuit is good. This is

because the main coil has operated and the auxiliary

T1-T2, T2-T3, and T1-T3. The controller is faulty if

contacts are holding the main contactor closed. Look for

there are no voltmeter readings on all three of the

trouble in the power circuit (the main contacts, overload

terminal pairs. You should then proceed to check the

relays, cable, and motor).

main contacts, overloads, and lead connections within

the controller. However, if there is voltage at all three

In the GSE rating you will come across various

terminals, the trouble is either in the motor or the wires

types of control circuits. Some control circuits are more

leading to the motor.

complex than the one shown in figure 5-21, while others

are simpler. The troubleshooting principles we have just

described will work on any type of control circuit. You,

Control Circuit Analysis

however, as the technician, must make certain you have

the correct schematics when you are troubleshooting

any type of electrical controller.

Suppose the overload reset buttons have been reset

and the START button is closed. If the main contacts do

BUS TRANSFER EQUIPMENT

not close, check the control circuit. Your testing

procedure should include the following steps:

Bus transfer equipment is installed at load centers,

1. Check for voltage in the controller at L1, L2, and

distribution panels, or loads that are fed by both normal

L3.

and alternate, or emergency feeders. Bus transfer

2. Place the voltmeter probes at points C and D (fig.

equipment allows you to select either the normal or

5-21). You should have a voltage reading when

alternate source of ship's service power. If an emergency

the STOP button is closed. You should have a

feeder is provided, the bus transfer unit will also allow

no-voltage reading when the STOP button is

you to get power from the emergency distribution

open. These conditions would indicate a good

system.

STOP button and control circuit fuse.

Automatic bus transfer (ABT) equipment allows

3. Next, check the voltage between points C and E.

you to select between two power supplies to obtain

T h e START button is good if you get a

power for the following systems:

no-voltage reading when the START button is

1. Emergency lighting

open. The START button is also good if you get

5-21