troubleshooting procedures are discussed in the

following paragraph.

Since thermocouples monitor temperature, you

must allow them to cool before you begin

troubleshooting. Thermocouples on GTEs can be cooled

by motoring the engine. You can check the

thermocouple and its leads by using a multimeter to take

resistance readings. Take resistance readings between

each pin and each pinto ground. Check the technical

manual to determine if the readings are within the

m i n i m u m acceptable limits. If the thermocouple

resistance system measurements are within limits,

troubleshoot the ship's instrumentation. As mentioned

earlier in this chapter, always refer to the manufacturer's

technical manual when you test, troubleshoot, and repair

any electrical equipment.

LEVEL CONTROL DEVICES

In the engineering plant on a gas turbine-powered

ship, operating personnel must know the levels of the

various liquids in different locations in the ship. The

level in the ship's freshwater tanks is an example of a

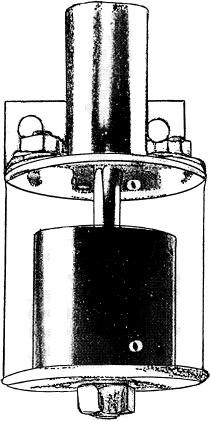

Figure 6-10.--Liquid-level float switch.

liquid level that must always be known. There are other

liquid levels that are also important. These include the

levels in the fuel oil service tanks, fuel oil stowage tanks,

liquid level reaches a preset point, the float switch

lubricating oil sumps, and drain tanks.

completes the circuit to the pump, signaling the pump

A wide variety of devices, some of them simple and

to start to remove the liquid from the tank. When the

s o m e complex, are available for measuring and

level drops to the preset point, the pump secures.

controlling liquid levels. Without level control devices,

engineering and operating personnel could not plan for

MAGNETIC FLOAT DEVICES

their supply needs. GSEs are responsible for the repair,

maintenance, and installation of these devices. Level

Each tank level indicator (TLI) system is made up

control devices used aboard gas turbine-powered ships

of equipment and accessories that are necessary for the

include liquid-level float switches and magnetic float

specific installation. The TLI system components can be

devices.

divided into four general groups: (1) the liquid-level

detection devices (transmitter), (2) the receiver devices

LIQUID-LEVEL FLOAT SWITCHES

(receiver panel or module), (3) the remote alarm or

liquid-level indicating devices (alarm and gauges), and

A relatively new development in indicating alarm

( 4 ) the accessories (tubing and so forth). These

and control functions is the liquid-level float switch. A

components are shown in figure 6-11.

liquid-level float switch is shown in figure 6-10. This

The purpose of the liquid-level detection devices

type of switch is usually found in tank- and bilge-level

installed in tanks is to convert the liquid level into an

alarm circuits.

electrical signal. The two types of detection devices

The liquid-level float switch has a

available are the transmitters and the level links.

doughnut-shaped, floatable magnetic core operating

Transmitters provide a continuous level measurement,

over an encapsulated reed switch. The entire assembly

w h i l e level links provide a point or incremental

is mounted at a predetermined level. The switch can be

measurement.

made normally open or closed by reversal of the core.

Study the transmitter shown in figure 6-12. The

Level conditions are shown as normal, above normal, or

transmitter consists of a network of voltage divider

below normal. The switch can also be used to start and

resistors and magnetic reed switches contained in silicon

stop pumps, such as in a drain tank system. When the

6-10