The rising-stem gate valve, shown in figure

6-3, has the stem attached to the gate; the gate

and stem rise and lower together as the valve is

operated.

Gate valves used in steam systems have flexible

gates. The reason for using a flexible gate is to

prevent binding of the gate within the valve when

the valve is in the closed position. When steam

lines are heated, they will expand, causing some

distortion of valve bodies. If a solid gate fits

snugly between the seat of a valve in a cold

steam system, when the system is heated and

pipes elongate, the seats will compress against

the gate, wedging the gate between them and

clamping the valve shut. This problem is over-

come by use of a flexible gate (two circular

plates attached to each other with a flexible hub

in the middle). This design allows the gate to flex

as the valve seat compresses it, thereby preventing

clamping.

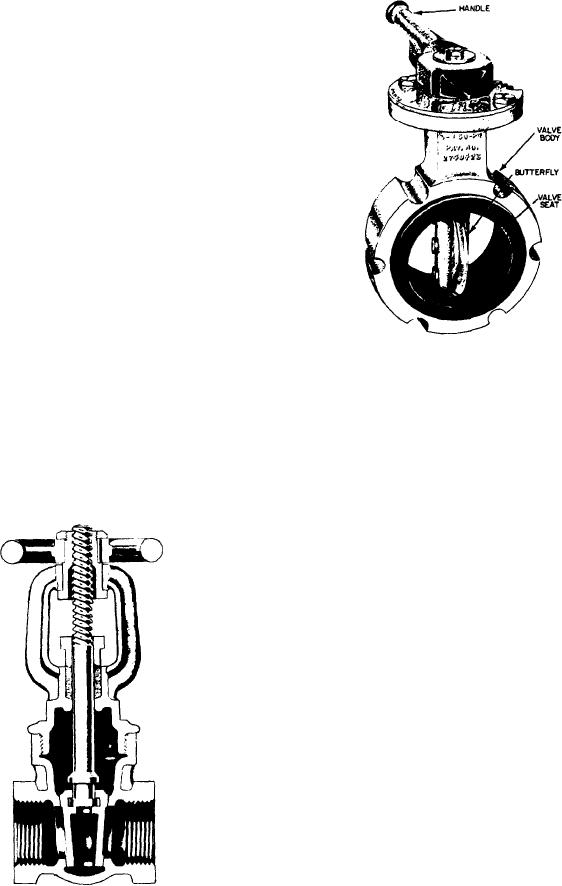

Figure 6-4.--Butterfly valve.

BUTTERFLY VALVES.--The butterfly

valve, one type of which is shown in figure 6-4,

may be used in a variety of systems aboard ship.

valve is light in weight, relatively small, relatively

These valves can be used effectively in freshwater,

quick-acting, provides positive shut-off, and can

saltwater, JP-5, F-76 (naval distillate), lube oil,

be used for throttling.

and chill water systems aboard ship. The butterfly

The butterfly valve has a body, a resilient seat,

a butterfly disk, a stem, packing, a notched

positioning plate, and a handle. The resilient seat

is under compression when it is mounted in the

valve body, thus making a seal around the

periphery of the disk and both upper and lower

points where the stem passes through the seat.

Packing is provided to form a positive seal around

the stem for added protection in case the seal

formed by the seat should become damaged.

To close or open a butterfly valve, turn the

handle only one quarter turn to rotate the disk

90. Some larger butterfly valves may have a

handwheel that operates through a gearing

arrangement to operate the valve. This method

is used especially where space limitation prevents

use of a long handle.

Butterfly valves are relatively easy to maintain.

The resilient seat is held in place by mechanical

means, and neither bonding nor cementing is

necessary. Because the seat is replaceable, the

valve seat does not require lapping, grinding, or

machine work.

BALL VALVES.--Ball valves, as the name

Figure 6-3.--Cutaway view of a gate valve (rising-stem

implies, are stop valves that use a ball to stop or

type).

6-3