pressure and to remain open until a specific reset

used in many drain lines and on the discharge side

pressure is reached-at which time they shut.

of many pumps.

Many different designs of these valves are used,

but the same result is achieved.

Special-Purpose Valves

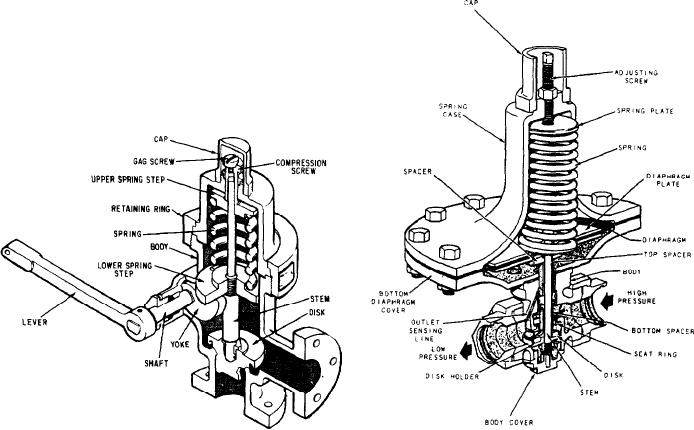

SPRING-LOADED REDUCING

There are many types of automatic pressure

VALVES.--Spring-loaded reducing valves, one

control valves. Some of them merely provide an

type of which is shown in figure 6-8, are used in

escape for pressures exceeding the normal

a wide variety of applications. Low-pressure air

pressure; some provide only for the reduction of

reducers and others are of this type. The valve

pressure; and some provide for the regulation of

simply uses spring pressure against a diaphragm

pressure.

to open the valve. On the bottom of the

diaphragm, the outlet pressure (the pressure in the

RELIEF VALVES.--Relief valves are

reduced pressure system) of the valve forces the

automatic valves used on system lines and equip-

disk upward to shut the valve. When the outlet

ment to prevent overpressurization. Most relief

pressure drops below the set point of the valve,

valves simply lift (open) at a preset pressure and

the spring pressure overcomes the outlet pressure

reset (shut) when the pressure drops only slightly

below the lifting pressure. Figure 6-7 shows a relief

and forces the valve stem downward, opening

valve of this type. System pressure simply acts

the valve. As the outlet pressure increases,

under the valve disk at the inlet of the valve. When

approaching the desired value, the pressure under

the diaphragm begins to overcome spring

system pressure exceeds the force exerted by the

pressure, forcing the valve stem upwards,

valve spring, the valve disk lifts off its seat, allow-

ing some of the system fluid to escape through

shutting the valve. You can adjust the downstream

the valve outlet until system pressure is reduced

pressure by removing the valve cap and turning

to just below the relief set point of the valve. The

the adjusting screw, which varies the spring

spring then reseats the valve. An operating lever

pressure against the diaphragm. This particular

is provided to allow manual cycling of the relief

valve or to gag it open for certain tests. Virtually

all relief valves are provided with some type of

device to allow manual cycling.

Other types of relief valves are the high-

pressure (HP) air safety relief valve and the bleed

air surge relief valve. Both of these types of valves

are designed to open completely at a specified lift

Figure 6-7.--Typical relief valve.

Figure 6-8.--Pressure-reducing (spring-loaded) valve.

6-5