oil filling and transfer system where provision

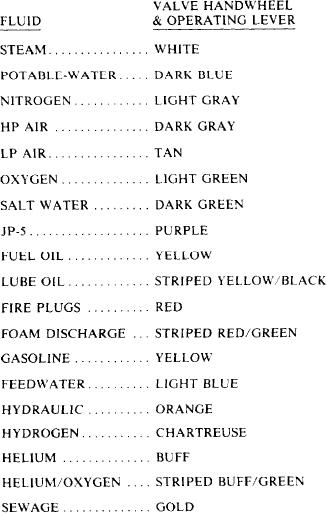

Table 6-1.--Valve Handwheel Color Code

must be made for the transfer of oil from any tank

to any other tank, to the service system, or to

another ship. If, for example, the purpose is to

transfer oil from tank No. 1 to tank No. 4, the

discharge valve for tank No. 4 and the suction

valve from tank No. 1 are opened, and all other

valves are closed. Fuel oil can now flow from tank

No. 1, through the suction line, through the

pump, through the discharge valve, and into tank

No. 4. The manifold suction valves are often of

the stop-check type to prevent draining of pumps

when they are stopped.

VALVE HANDWHEEL

IDENTIFICATION AND

COLOR CODING

Valves are identified by markings inscribed on

the rims of the handwheels, by a circular label

plate secured by the handwheel nut, or by label

plates attached to the ship's structure or to the

adjacent piping.

Piping system valve handwheels and operating

levers are marked for training and casualty

control purposes with a standardized color code.

Color code identification is in conformance with

the color scheme of table 6-1. Implementation of

this color scheme provides uniformity among all

naval surface ships and shore-based training

facilities.

MAINTENANCE

Preventive maintenance is the best way

manufacturer: type of system (oil, water, gas),

to extend the life of valves and fittings.

operating pressure, direction of flow, and other

Always refer to the applicable portion of the

information.

Standard Navy Valve Technical Manual, NAV-

Y o u should also know the operating

SEA 0948-LP-012-5000, if possible. When making

characteristics of the valve, the metal from which

repairs on more sophisticated valve types, use the

it is made, and the type of end connection with

available manufacturer's technical manuals. As

which it is fitted. Operating characteristics and

soon as you observe a leak, determine the cause,

the material are factors that affect the length and

and then apply the proper corrective maintenance.

kind of service that a valve will give; end

Maintenance may be as simple as tightening a

connections indicate whether or not a particular

packing nut or gland. A leaking flange joint may

valve is suited to the installation.

need only to have the bolts tightened or to have

When you install valves, ensure they are

a new gasket or O-ring inserted. Dirt and scale,

readily accessible and allow enough headroom for

if allowed to collect, will cause leakage. Loose

full operation. Install valves with stems pointing

hangers permit sections of a line to sag, and the

upward if possible. A stem position between

weight of the pipe and the fluid in these sagging

straight up and horizontal is acceptable, but avoid

sections may strain joints to the point of leakage.

the inverted position (stem pointing downward).

Whenever you are going to install a valve, be

If the valve is installed with the stem pointing

sure you know the function the valve is going to

downward, sediment will collect in the bonnet and

perform-that is, whether it must start flow, stop

score the stem. Also, in a line that is subject to

flow, regulate flow, regulate pressure, or

freezing temperatures, liquid that is trapped in the

prevent backflow. Inspect the valve body for the

valve bonnet may freeze and rupture it.

information that is stamped upon it by the

6-10