condensate level in the trap body. The bucket

valve is connected to the bucket in such a way that

the valve closes as the bucket rises. As condensate

continues to flow into the trap body, the valve

remains closed until the bucket is full. When the

bucket is full, it sinks and thus opens the valve.

The valve remains open until enough condensate

has blown out to allow the bucket to float, thus

closing the valve.

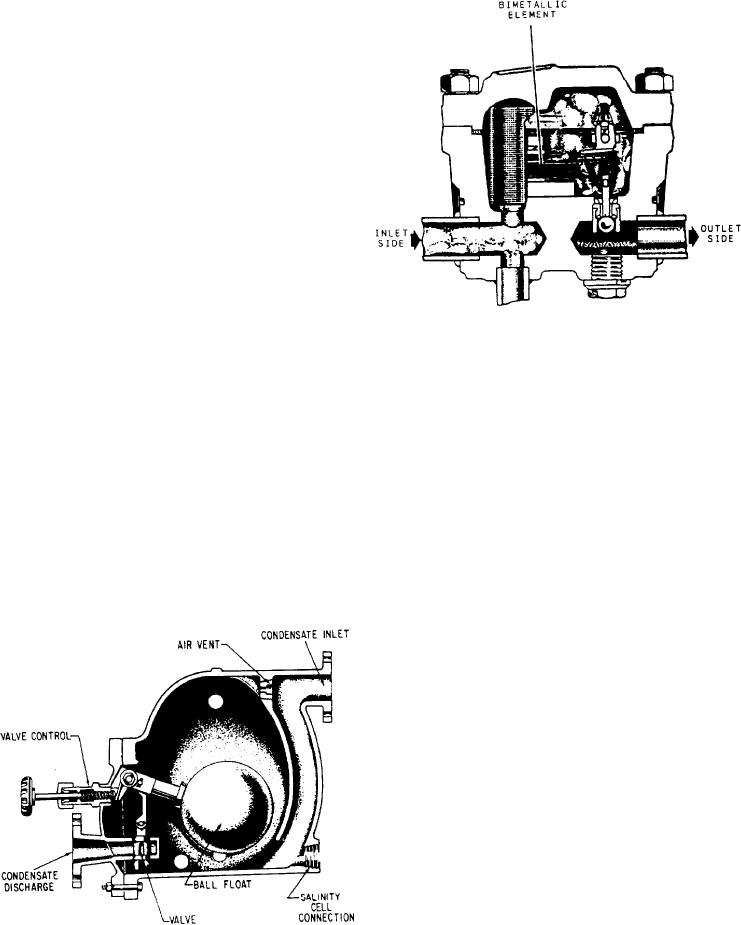

Figure 6-18 shows a ball-float steam trap. This

trap works much in the same way as the bucket

trap. Condensate and steam enter the body of the

trap, and the condensate collects at the bottom.

As the condensate level rises, the ball float rises

until it is raised enough to open the outlet valve

of the trap. When the outlet valve opens, the

condensate flows out of the trap into the drain

system, and the float level drops, shutting off the

valve until the condensate level rises again.

Figure 6-19.--Bimetallic steam trap.

Bimetallic Steam Traps

fastened to the top of the stem of the ball-type

check valve.

Bimetallic steam traps of the type shown in

Line pressure acting on the check valve keeps

figure 6-19 are used in many ships to drain

the valve open. When steam enters the trap body,

condensate from main steam lines, auxiliary steam

the bimetallic element expands unequally because

lines, and other steam components. The main

of the different response to the temperature of

working parts of this steam trap are a segmented

the two metals; the bimetallic element deflects up-

bimetallic element and a ball-type check valve.

ward at its free end, thus moving the valve stem

The bimetallic element has several bimetallic

upward and closing the valve. As the steam cools

strips fastened together in a segmented fashion,

and condenses, the bimetallic element moves

as shown in figure 6-19. One end of the bimetallic

downward, toward the horizontal position, thus

element is fastened rigidly to a part of the valve

opening the valve and allowing some condensate

body; the other end, which is free to move, is

to flow out through the valve. As the flow of

condensate begins, an unbalance of line pressure

across the valve is created; since the line pressure

is greater on the upper side of the ball of the check

valve, the valve now opens wide and allows a full

capacity flow of condensate.

Orifice Steam Traps

Aboard ship, continuous-flow steam traps of

the orifice type are used in systems or services in

which condensate forms at a fairly steady rate.

Figure 6-20 shows one orifice-type steam trap.

Several variations of the orifice-type steam

trap exist, but all have one thing in common-

they have no moving parts. One or more restricted

passageways or orifices allow condensate to trickle

through but do not allow steam to flow through.

Besides orifices, some orifice-type steam traps

have baffles.

Figure 6-18.--Hall-float steam trap.

6-14