Keep a check on the working surface of

Coils, rings, and corrugated ribbon are the

common forms of packing used in valves. The

the lap. If a groove develops, have the lap

form of packing to be used in repacking a

refaced.

particular valve will depend on the valve size,

Always use clean compound for lapping.

application, and type. Packing materials will be

discussed in tnore detail later in this chapter.

Replace the compound frequently.

Spread the compound evenly and lightly.

STEAM TRAPS

Steam traps are installed in steam lines to drain

Do not lap more than is necessary to

condensate from the lines without allowing the

produce a smooth even seat.

escape of steam. There are many different designs

of steam traps; some are suitable for high-pressure

Always use a fine grinding compound to

use and others for low-pressure use.

finish the lapping job.

TYPES OF STEAM TRAPS

Upon completion of the lapping job, spot-

in and grind-in the disk to the seat.

Some types of steam traps that are used in the

Navy are the mechanical steam traps, bimetallic

You should use only approved abrasive

steam traps, and orifice-type steam traps.

compounds for reconditioning valve seats and

disks. Compounds for lapping valve disks and

Mechanical Steam Traps

seats are supplied in various grades. Use a coarse

grade compound when you find extensive

Mechanical steam traps in common use in-

corrosion or deep cuts and scratches on the disks

clude bucket-type traps and ball-float traps.

and seats. Use a medium grade compound as a

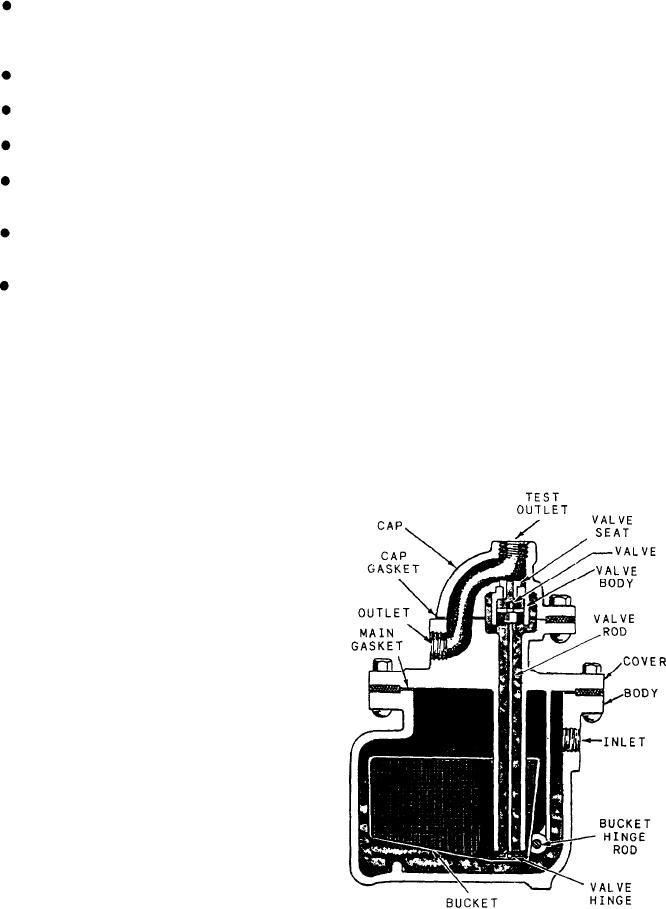

The operation of the bucket-type steam trap,

follow-up to the coarse grade; you may also use

shown in figure 6-17, is controlled by the

it to start the reconditioning process on valves that

are not too severely damaged. Use a fine grade

compound when the reconditioning process nears

completion. Use a microscopic-fine grade for

finish lapping and for all grinding-in.

Refacing Valves

Badly scored valve seats must be refaced in

a lathe, with a power grinder, or with a valve

reseating machine. However, the lathe, rather

than the reseating machine, should be used for

refacing all valve disks and all hard-surfaced valve

seats. Work that must be done on a lathe or with

a power grinder should be turned over to shop

personnel.

Repacking Valves

If the stem and packing of a valve are in good

condition, you can normally stop packing gland

leaks by tightening up on the packing. You must

be careful, however, to avoid excessive thread

engagement of the packing gland studs (if used)

and to avoid tightening old, hardened packing

which will cause the valve to seize. Subsequent

operation of such a valve may score or bend the

stem.

Figure 6-17.--Bucket-type steam trap.

6-13