To grind-in a valve, first apply a light coating

Spotting-In Valves

of grinding compound to the face of the disk.

Then insert the disk into the valve and rotate the

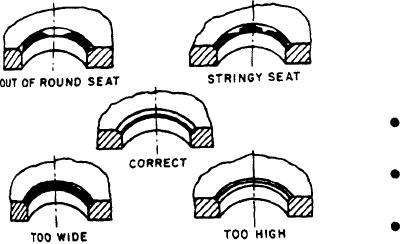

The method used to visually determine

disk back and forth about one-quarter turn; shift

whether the seat and the disk of a valve make

the disk-seat relationship from time to time so the

good contact with each other is called spotting-

disk will be moved gradually, in increments

in. To spot-in a valve seat, you first apply a thin

through several rotations. During the grinding

coating of Prussian blue (commonly called Blue

process, the grinding compound will gradually be

Dykem) evenly over the entire machined face

displaced from between the seat and disk surfaces;

surface of the disk. Insert the disk into the valve

therefore, you must stop every minute or so to

and rotate it one-quarter turn, using a light

replenish the compound. When you do this, wipe

downward pressure. The Prussian blue will adhere

both the seat and the disk clean before applying

to the valve seat at those points where the disk

the new compound to the disk face.

makes contact. Figure 6-16 shows the appearance

When you are satisfied that the irregularities

of a correct seat when it is spotted-in; it also shows

have been removed, spot-in the disk to the seat

the appearance of various kinds of imperfect

in the manner previously described.

seats.

Grinding-in is also used to follow up all

After you have noted the condition of the seat

machining work on valve seats or disks. When the

surface, wipe all the Prussian blue off the disk

valve seat and disk are first spotted-in after they

face surface. Apply a thin, even coat of Prussian

have been machined, the seat contact will be very

blue to the contact face of the seat and place the

narrow and will be located close to the bore.

disk on the valve seat again and rotate the disk

Grinding-in, using finer and finer compounds as

one-quarter turn. Examine the resulting blue ring

the work progresses, causes the seat contact to

on the valve disk. The ring should be unbroken

become broader. The contact area should be a

and of uniform width. If the blue ring is broken

perfect ring covering about one-third of the

in any way, the disk is not making proper

seating surface.

contact with the seat.

Be careful to avoid overgrinding a valve seat

or disk. Overgrinding will produce a groove in the

Grinding-In Valves

seating surface of the disk; it will also round

off the straight, angular surface of the disk.

The manual process used to remove small

Machining is the only process by which over-

irregularities by grinding together the contact

grinding can be corrected.

surfaces of the seat and disk is called grinding-

in. Grinding-in should not be confused with

refacing processes in which lathes, valve reseating

Lapping Valves

machines, or power grinders are used to re-

condition the seating surfaces.

When a valve seat contains irregularities that

are slightly larger than can be satisfactorily

removed by grinding-in, the irregularities can be

removed by lapping. A cast-iron tool (lap) of

exactly the same size and shape as the valve disk

is used to true the valve seat surface. The follow-

ing are some precautions you should follow when

lapping valves:

Do not bear heavily on the handle of the

lap.

Do not bear sideways on the handle of the

lap.

Change the relationship between the lap

and the valve seat occasionally so that the

lap will gradually and slowly rotate around

the entire seat circle.

Figure 6-16.--Examples of spotted-in valve seats.

6-12