plugs (fig. 6-21) also are used in some strainers

to trap iron and steel particles carried by fluid.

Studies have indicated that even particles as small

as 1 to 5 microns have a degrading effect, causing

failures and hastening deterioration in many cases.

There will always be controversy over the

exact definitions of filters and strainers. In the

past, many such devices were named filters but

technically classed as strainers. To minimize

the controversy, the National Fluid Power

Association gives us these definitions:

FILTER --A device whose primary function

is the retention, by some porous medium, of

insoluble contaminants from a fluid.

STRAINER--A coarse filter.

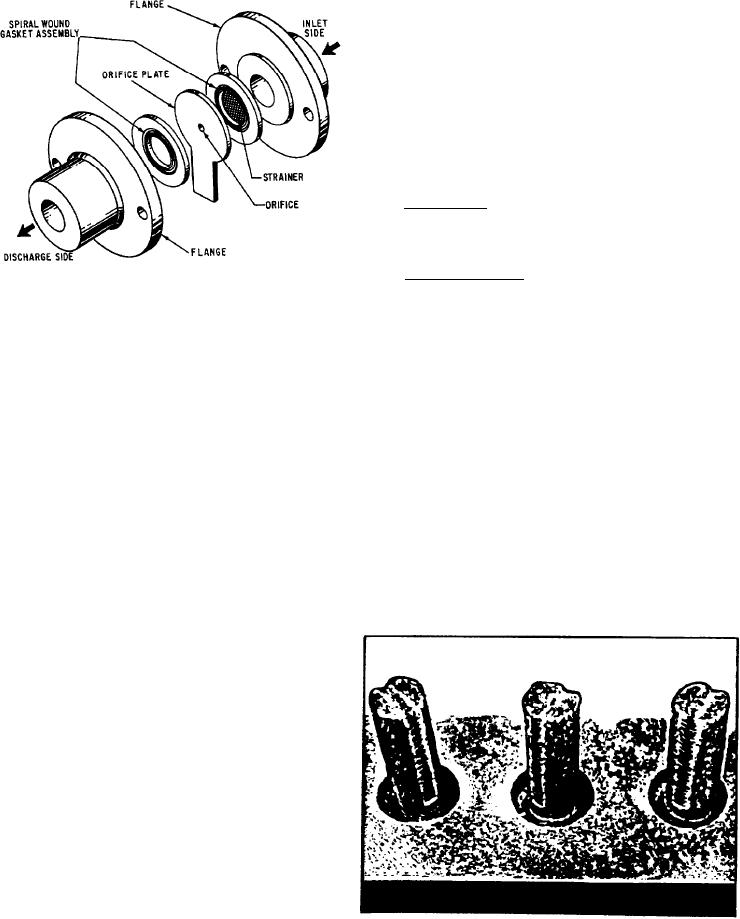

Figure 6-20.--Constant-flow drain orifice.

To put it simply, whether the device is a filter

or a strainer, its function is to trap contaminants

MAINTENANCE

from fluid flowing through it. "Porous medium"

simply refers to a screen or filtering material that

A strainer is installed just ahead of each steam

allows fluid flow through it but stops various

trap. The strainer must be kept clean and in good

other materials.

condition to keep scale and other foreign matter

from getting into the trap. Scale and sediment can

clog the working parts of a steam trap and

MESH AND MICRON RATINGS

seriously interfere with the working of the trap.

Steam traps that are not operating properly

Filters, which may be made of many materials

can cause problems in systems and machinery.

other than wire screen, are rated by MICRON

One way to check on the operation of a steam trap

size. A micron is one-millionth of a meter or

is to listen to it. If the trap is leaking, you will

39-millionths of an inch. For comparison, a grain

probably be able to hear it blowing through.

of salt is about 70 microns across. The smallest

Another way to check the operation of steam traps

particle visible to the naked eye is about

is to check the pressure in the drain system. A

leaking steam trap causes an unusual increase in

pressure in the drain system. When observing this

condition, you can locate the defective trap by

cutting out (isolating from the system) traps, one

at a time, until the pressure in the drain system

returns to normal.

You should disassemble, clean, and inspect

defective steam traps. After determining the cause

of the trouble, repair or replace parts as required.

In some steam traps, you can replace the main

working parts as a unit; in others, you may have

to grind in a seating surface, replace a disk, or

perform other repairs. You should reseat defective

trap discharge valves. Always install new gaskets

when reassembling steam traps.

FILTERS AND STRAINERS

Fluids are kept clean in a system principally

by devices such as filters and strainers. Magnetic

Figure 6-21.--Magnetic plugs.

6-15