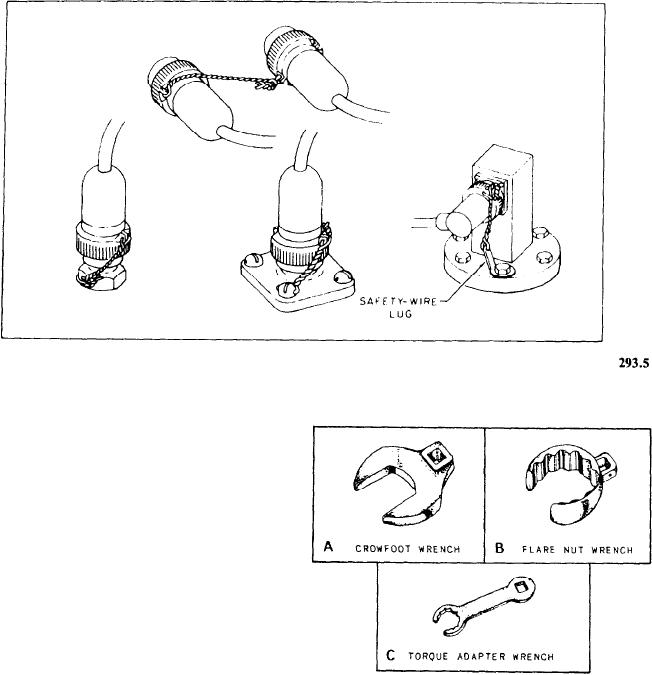

Figure 3-3.--Safety-wiring electrical connectors.

Figures 3-2 and 3-3 show examples of safety-

wiring techniques that you should follow. The

figures do not show all possible safety-wiring

combinations; however, safety-wiring practices

should conform to those shown. Consult specific

manufacturers' technical manuals for approved

materials and techniques to use in any given

application. You will find step-by-step procedures

for safety-wiring in Propulsion Gas Turbine

Module LM2500, Trouble Isolation, volume 2,

part 3, S9234-AD-MMO-050/LM2500, section

8.1.

WRENCHES

While performing your maintenance pro-

cedures, you will use a variety of wrenches. This

Figure 3-4.--Crowfoot, flare nut, and torque adapter

section is about the recommended wrenches you

wrenches.

need to be familiar with while working on the gas

turbine engine (GTE). You will also learn

about wrenches and hand tools that are not

maintenance procedures. You can use it to gain

recommended for use on the GTE.

accessibility to hard to reach areas where other

wrenches are difficult to use. The head of

Recommended Wrenches

the wrench is designed like an open-end

wrench. However, the other end is designed to

The only hand tools you should use on GTEs

accommodate accessories, such as extensions,

are chrome-plated, nickel-plated, or unplated

breaker bars, and torque wrenches. Crowfoot

hand tools. The CROWFOOT wrench (fig. 3-4,

wrenches come in a wide variety of sizes like those

view A) is a very handy tool to use for

of the open-end type of wrenches.

3-3