you to use while working on GTEs. You might,

The FLARE NUT wrench (fig. 3-4, view B)

however, use them elsewhere for maintenance.

is similar to a box wrench. The difference is a slot

The ADJUSTABLE wrench is useful because

cut in the wrench head which allows it to fit over

it will fit nuts and bolts that are odd-sized or

tubing or wiring and then onto the fastener. There

slightly damaged or burred. BUT, good engineer-

are two types of this wrench you might use on

ing practice dictates that you use the proper size

your ship. The first type is long handled, similar

wrench for the work you are doing. Parts on the

to the regular box wrench, with a different size

GTEs are made of high-quality materials and are

on each end. The second type is short. The other

standard sizes. Because of the design of the

end is designed to accommodate accessories, such

adjustable wrench, it could cause extensive

as extensions, breaker bars, and torque wrenches.

damage to the GTE. If it slips, gouging and/or

These flare nut wrenches are made with 6, 8, 12,

scratching could occur. Do not use a part if it is

and 16 points or notches. The wrenches on your

damaged in any way.

ship will generally be 12 points because of the

DO NOT use CADMIUM-PLATED or

numerous 12-point fasteners used on the GTE.

SILVER-PLATED hand tools when working on

You can also use the 12-point wrench effectively

titanium parts of GTEs. If you use these hand

on 6-point (hex head) fasteners. As with the

tools, you could cause particles of cadmium or

crowfoot wrenches, the flare nut wrenches come

silver to become imbedded in the titanium parts.

in a wide variety of sizes.

At temperatures above 600F, the cadmium or

The TORQUE ADAPTER wrench (fig. 3-4,

silver can cause embrittlement. This results in

view C) is similar to a box wrench. The other end

overstressed areas and possible cracking. To

is designed to accommodate accessories, such as

prevent this, use chrome-plated, nickel-plated, or

extensions, breaker bars, and torque wrenches.

unplated hand tools on titanium parts.

They are used to reach nuts and bolts that are in

hard to reach locations.

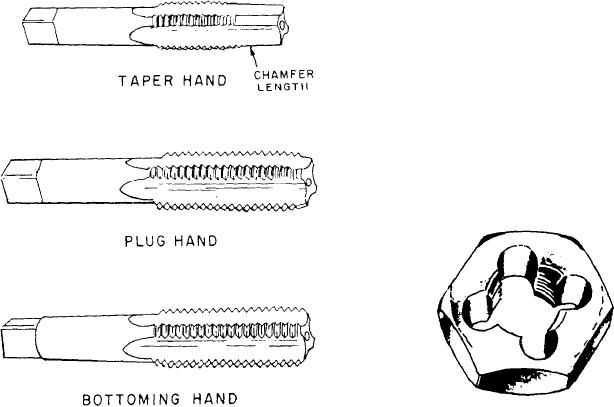

TAPS AND DIES

Nonrecommended Wrenches

and Hand Tools

Taps and dies are used to cut threads in metal,

plastics, or hard rubber. The taps are used for

The adjustable wrench and cadmium-plated

cutting internal threads, and the dies are used to

or silver-plated tools are NOT recommended for

cut external threads. Many different types of taps

are available. However, the most common are the

taper, plug, and bottoming (fig. 3-5).

The taper (starting) hand tap has a chamfer

length of 8 to 10 threads. You would use these

taps when starting a tapping operation and when

tapping through holes.

Plug hand taps have a chamfer length of 3 to 5

threads and are designed for use after the taper

tap.

Bottoming hand taps are used for threading

the bottom of a blind hole. They have a very short

chamfer length of only 1 to 1 1/2 threads. This

Figure 3-6.--Rethreading die.

Figure 3.5.--Types of common taps.

3-4