a signal mechanism automatically issues an

and standards will prevent this. Torque

audible click. Next the handle releases, or

wrenches must be kept in calibration. Ensure you

" b r e a k s , " and moves freely for a short

use ONLY calibrated torque wrenches.

distance. You can easily feel the release

and free travel and know when the torquing

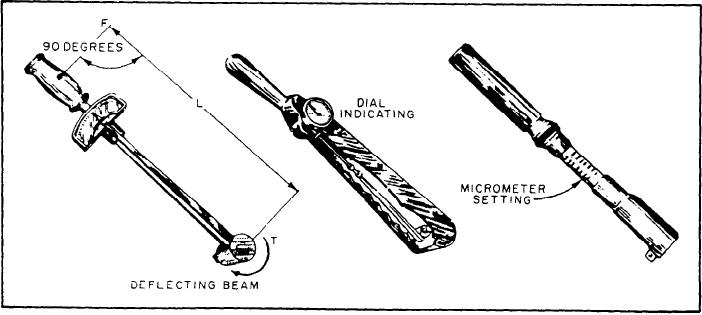

Types of Torque Wrenches

process is complete.

The procedure for using the deflecting

beam and the dial indicating wrenches is

The three most commonly used torque

the same as the micrometer setting wrench;

wrenches are the deflecting beam, dial in-

however, you have to hold the torque at

dicating, and micrometer setting types (fig. 3-14).

the desired value until the reading is steady.

When using the deflecting beam and the dial

indicating torque wrenches, you read the torque

Torque Values

on a dial or scale mounted on the handle of the

wrench.

Torque values are expressed in pound-

The torque wrench you will probably

inches (lb-in.) or pound-feet (lb-ft). One pound-

use is the micrometer setting. This type is

inch (or 1 pound-foot) is the twisting force

of 1 pound applied to a twist fastener (such

easier to use because you do not have to

as a bolt or nut) with 1 inch (or 1 foot)

watch a dial or pointer while using the

of leverage. This twisting force is applied

wrench.

to the fastener to secure the components.

When you are working with or reading torque

To use a micrometer setting wrench, un-

lock the grip and adjust the handle to the

values, they are usually expressed in inch-

desired setting on the micrometer scale. Then,

pounds (in.-lb) or foot-pounds (ft-lb).

relock the grip. Install the required socket

A manufacturer's or a technical manual

or adapter to the square drive of the handle.

generally specifies the amount of torque you

Place the wrench assembly on the nut or

should apply to a fastener. To assure getting

the correct amount of torque on the fastener,

bolt and pull in a clockwise direction with

use the wrench according to the manufacturer's

a smooth, steady motion. (A fast or jerky

instructions. When using an adapter (such

motion results in an improperly torqued unit.)

as a crowfoot wrench) with a torque wrench,

When the applied torque reaches the torque

value, which is indicated on the handle setting,

you must calculate the correct adapter torque.

Figure 3-14.--Torque wrenches.

3-9