specifies a thread lubricant, use it to obtain the

a nontorque wrench and retighten to the correct

most accurate torque reading.

torque with the indicating torque wrench.

6. Do not use a torque wrench before check-

Torque wrenches are delicate and expensive

ing its calibration date. Calibration intervals have

tools. Observe the following precautions when

using them :

been established for all torque tools used in the

Navy. When a tool is calibrated by a qualified

calibration activity at a shipyard, tender, or repair

1. Do not move the setting handle below the

ship, a label showing the next calibration due date

lowest torque setting when you use the micrometer

is attached to the handle. Check this date before

setting. However, place it at its lowest setting prior

to returning it to storage.

you use a torque tool to ensure that it is not over-

2. Do not use the torque wrench to apply

due for calibration.

greater amounts of torque than its rated capac-

ity.

You can find specific information on torque

values for equipment in the manufacturer's

3. Do not use the torque wrench to break

loose bolts that have been previously tightened.

technical manual.

4. Do not drop the wrench. The resulting jolt

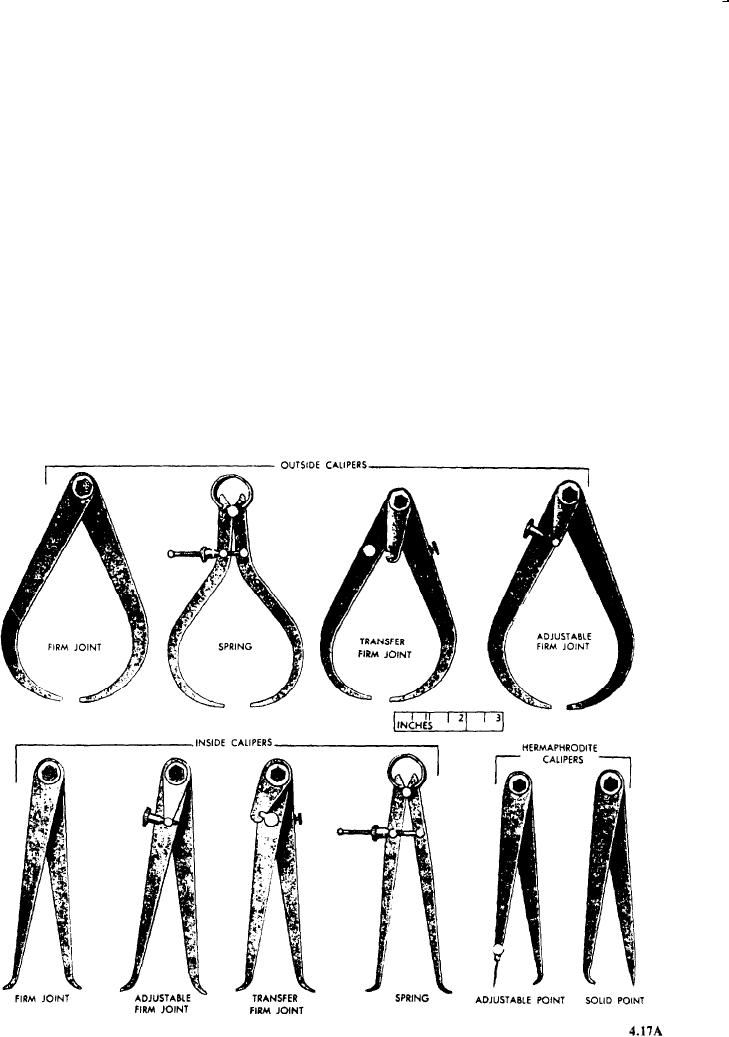

SIMPLE CALIPERS

can affect its accuracy.

5. Do not apply a torque wrench to a nut that

Simple calipers are used in conjunction

has been tightened. Back off the nut one turn with

with a scale to measure diameters. Figure 3-16

Figure 3-16.--Simple calipers-noncalibrated.

3-11