three-position lever selects one of three posi-

tions-ENGAGED, DISENGAGED, or SHAFT

LOCKED. Figure 8-9 shows cross-sectional views

of the turning gear mechanism in all three posi-

tions. In the disengaged position, the handle can

be padlocked to a bracket to prevent accidental

movement of the operating lever. Do not attempt

to engage the turning gear while the reduction gear

is operating. Also, do not attempt to operate the

turning gear with the operating lever in the shaft

locked position. Either of these actions will result

in equipment or personnel casualties. With the

turning gear engaged, the gear may be rotated

manually with a wrench. A limit switch assembly

provides electrical signals for TURN GEAR

ENGAGED and SHAFT LOCKED indicators at

the PACC and the PLCC and a disengaged signal

for the ECSS logic. The MRG lube oil header

must have 15 psig of pressure to operate the

turning gear motor.

The drive motor for the turning gear is a

440-volt, 3-phase, 60-hertz electric motor, rated

5 horsepower (hp) at 1,200 rpm. It drives the

turning gear drive shaft through a worm gear. The

turning gear assembly is lubricated by oil sprays

from the MRG lube oil supply header and a self-

contained oil sump.

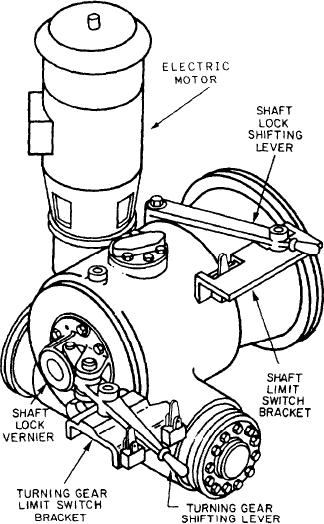

CG CLASS SHIPS.--An electric-motor-

driven, double-reduction turning gear assembly

is mounted on each MRG (fig. 8-10). When

engaged, the turning gear drives through the

upper outboard second-reduction pinion. The

assembly consists of a 7.5-hp-driven motor and

Figure 8-10.--Turning gear assembly (CC class ships).

a double-reduction, spiroid/worm-type speed

reducer. The turning gear assembly is attached to

the MRG through the second-reduction housing

used to engage and disengage the turning gear

flange and the shaft lock ring (stop gear). A

clutch.

flexible coupling attaches the drive motor shaft

The shaft lock shifting lever moves the shaft

to the spiroid pinion in the first-reduction

lock clutch with a shifting yoke. An index plate,

housing. A coupling guard covers the flexible

mounted on the housing, and an indicator plate,

coupling. All bearings in the turning gear

mounted on the worm shaft, make up a turning

assembly are antifriction bearings. Lubrication is

gear shaft lock vernier. This vernier indicates

accomplished by a combination oil immersion and

when shaft lock male clutch teeth are in line with

spray system supplied from the MRG lube oil

the female clutch teeth attached to the turning gear

system at a rate of 3 gpm. The splined gears are

housing. The shaft lock shifting lever locks the

spray-lubricated; the worm gears are lubricated

shaft lock movable male clutch teeth to the

by gear meshes and bearings dipping into a self-

stationary female clutch teeth attached to the

contained reservoir.

turning gear housing. Plates on the gear lock limit

Two shifting levers are provided with the

switch bracket identify two positions of the shaft

turning gear. The shaft lock shifting lever is

lock shifting lever: SHAFT UNLOCKED and

mounted on top of the unit and is used to lock

SHAFT LOCKED. The vernier indicator is used

the shaft adapter to the shaft lock ring. The other

to align the clutch teeth, while an open-end

lever, the turning gear shifting lever, is mounted

wrench is used to rotate the shaft during mating

on the back of the turning gear assembly and is

of the teeth. Limit switches send signals to the

8-19