ECSS to indicate the status of the shifting lever.

Override stops are provided on the clutch and

shaft lock limit switch brackets to prevent the

shifting levers from moving past the microswitch

positions.

The turning gear shifting lever is connected to

the turning gear clutch via the clutch shaft.

Shifting this lever can engage or disengage

the clutch from the shaft adapter. The shifting

levers can be padlocked to the disengaged

positions to prevent accidental engagement of

the turning gear while the MRG is operating.

Two plates on the clutch limit switch bracket iden-

tify the shifting lever position: TURNING GEAR

D I S E N G A G E D and TURNING GEAR

ENGAGED. The connect-disconnect coupling

moves in the axial direction to engage or

disengage. The shifting lever axially engages or

disengages the internal gear teeth with mating

teeth on the end of the second-reduction pinion

shaft.

The turning gear provides a means for rotating

the propeller shaft while the propulsion plant is

shut down. The second-reduction gear shaft and

propeller shaft rotate at about 0.1 rpm with the

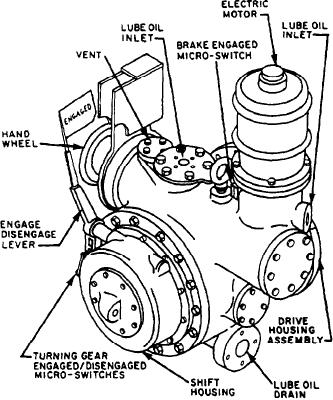

Figure 8-11.--Turning gear assembly (FFG class ships).

turning gear engaged and operating. This slow

speed permits inspection of the MRG gear teeth.

When the turning gear is locked, a microswitch

The slow rpm also permits MRG cooldown

that is actuated by the brake lever provides a brake

without shaft distortion or bending. Turning also

locked signal to the PCC. A handwheel is also

prevents propeller shaft bowing. The circuit

provided for turning the turning gear manually.

permissives which must be satisfied to engage

The gearbox for the turning gear has a worm gear

the turning gear are as follows:

drive system.

Shaft not locked

The electric motor is controlled by a magnetic

controller that is mounted remotely from the

Greater than 9 psig lube oil pressure

MRG. The motor is designed to operate in either

No GTE running

the forward or reverse direction.

No clutch engaged (Turning gear motor can-

Lubricating Pump

not be engaged if either clutch is engaged.)

The lube oil system in each MER incorporates

three positive-displacement pumps. Two of the

FFG CLASS SHIPS.--Figure 8-11 shows the

pumps are driven by electric motors, while the

turning gear assembly on the FFG class ships. It

third is driven by the MRG and is designated the

is mounted on the aft end of the port HS pinion.

attached pump. The purpose of the attached

It has a shift lever for engagement or disengage-

pump is to augment the output of the electric

ment. Two microswitches associated with the shift

pumps during propulsion plant operation. This

lever provide electrical signals to the propulsion

pump is a vertical-screw, submerged-suction

control console (PCC) and the local operating

pump, with a nominal flow of 1,140 gpm at 1,220

panel (LOP) when the shift lever is engaged or

rpm pump speed. The motor-driven pumps are

disengaged.

of similar construction, but they have a smaller

The turning gear assembly includes a 5-hp

capacity.

electric motor that operates from a 440-volt,

The attached pump is driven by the lower

60-hertz, 3-phase power source, The coupling

inboard second-reduction pinion shaft through a

between the electric motor and the turning gear

manually operated connect/disconnect coupling

train includes a mechanically operated brake. This

and a right-angle drive unit. Figure 8-12 shows

brake is used to lock the turning gear and may

this right-angle drive.

also be used to lock the entire reduction gear train.

8-20