control functions as well as for indications of

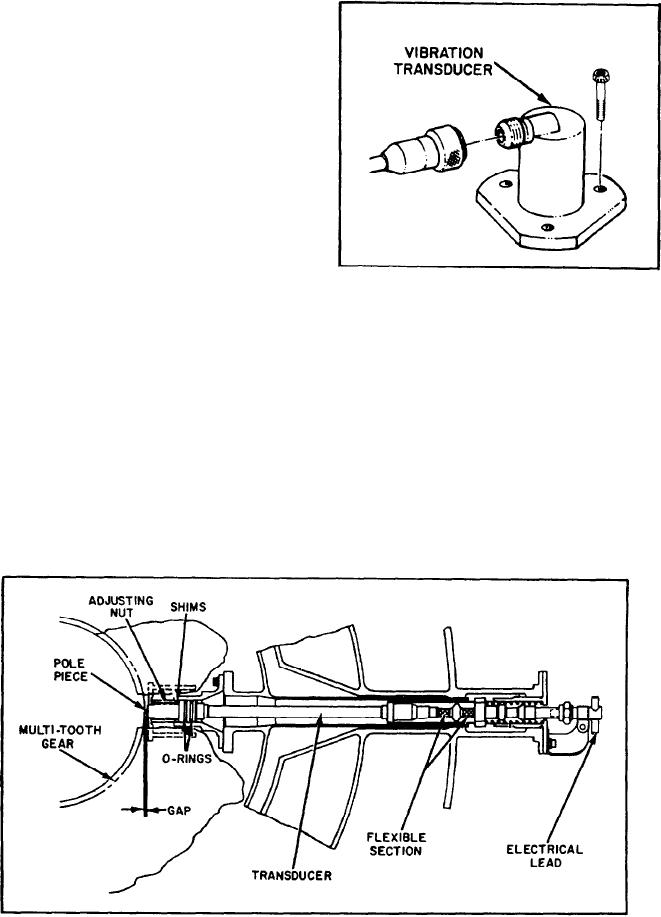

equipment speed. Figure 5-32 shows the magnetic

speed pickup transducer used in an LM2500

power turbine.

The most important thing you should

remember when replacing a speed pickup is to

check the depth setting. You can measure the

depth clearance with either a special tool supplied

by the equipment manufacturer or a depth

micrometer. Set the proper clearance by using

either shims or locknuts. If you do not set the

clearance properly, the magnetic sensor will be

either too close to the toothed gear or too far from

it. If it is too close, it may be damaged by the

rotating gear. If it is too far from the gear, the

unit will fail to give the proper voltage signal.

Always refer to the appropriate manufacturer's

technical manual when you replace a magnetic

Figure 5-33.--Velocity vibration transducer.

speed sensor.

The vibration pickup is a linear velocity

VIBRATION SENSORS

transducer (transfers mechanical energy to

electrical energy). The magnetic circuit is closed

One of the first indications of internal damage

through the circular air gap between the pole piece

to gas turbines is high vibration. High-vibration

sleeve in the case and the pole pieces on the

conditions can be indications of failed bearings,

magnet assembly. The air gap is interrupted by

damaged blading, or a dirty compressor. The GTEs found

the coils. (The flux field in the air gap is

on Navy ships use velocity vibration and accelerometer-

normally aligned with the approximate midpoint

type pickups. Figure 5-33 shows a typical velocity

of the two coils by the centering action of the two

vibration pickup used on GTEs.

springs.) As the engine vibrates, the rigidly

Figure 5-32.--Magnetic speed pickup used on the LM2500 power turbine.

5-23