is the lever operated switch. It is activated by a

physical arrangement of some tanks makes this

horizontal lever attached to a float. The float is

necessary. When multiple sections are used, they

located inside the tank. When the liquid level

are electrically connected as one continuous

reaches a preset point, the lever activates the

divider network.

switch.

Two types of floats are used. In noncompen-

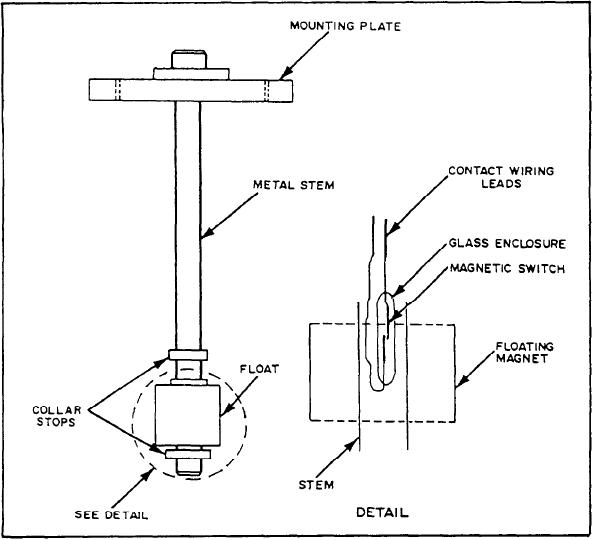

The other type of level switch uses a magnet-

sated tanks, the float is designed to float at the

equipped float sliding on a vertical stem. The stem

surface of the fuel or JP-5. For seawater

contains a hermetically sealed, reed switch. The

compensated tanks, the float is designed to stay

float moves up and down the stem with the liquid

at the seawater/fuel interface.

level. It magnetically opens or closes the reed

switch as the float passes over it. Figure 5-23

shows the construction of the magnetically

CONTACT LEVEL SENSORS

operated float switch. Magnetic float switches

may be constructed with more than one float on

Many times you do not have to know the exact

a stem. This type of switch can detect multiple

level of a tank until it reaches a preset level. When

levels in the same tank, such as a high- and low-

this type of indication is needed, you can use a

level alarm. You may also wire multiple stems

contact or float switch. Two types of float level

together to provide this same feature.

switches are used on gas turbine ships. One type

Figure 5-23.--Magnetic float switch.

5-18