The sensor used for indicating a tank level is

Setting Pressure Switches

commonly called a tank level indicator (TLI). This

sensor will tell you the exact amount of liquid in

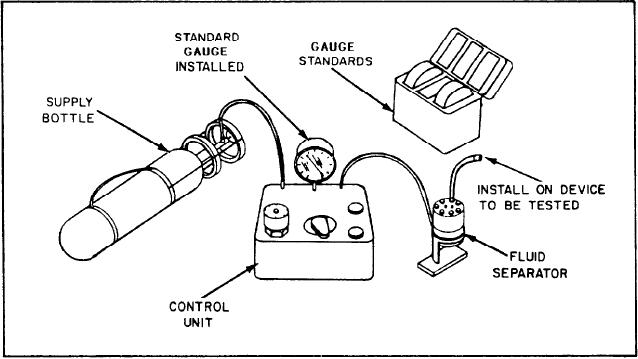

To set a pressure switch, you first have to set

a tank. In the following paragraphs we will

a known pressure in the operational range of the

describe the operation of each of these sensors and

switch. Normally, you do this by using a test setup

their applications. Refer to the manufacturers'

like that shown in figure 5-22. In an emergency,

technical manuals for more information on the

you can use the pressure of the system in which

procedures used to adjust each type of device.

the switch is installed. But you should reset the

switch as soon as possible using a calibrator.

Many types of pressure calibrators are used in the

TANK LEVEL INDICATORS

fleet. Refer to the manufacturer's technical

manual for the correct operating instructions for

Many tank levels on gas turbine ships are

your unit.

monitored to provide the exact liquid level in

them. Fuel tanks, for example, are monitored to

The adjustments on the pressure switches are

the same as the adjustments on the temperature

ensure they do not overflow. They are also

switches that we described earlier in this chapter.

monitored to let the engineer officer know the

amount of fuel aboard the ship. The sensors

used to monitor these levels are TLIs. Each of the

level-monitored tanks contains a level transmitter.

LIQUID LEVEL INDICATORS

A typical transmitter section contains a voltage

In a gas turbine propulsion plant, you will

divider resistor network extending the length of

have to monitor systems and tanks for liquid level.

the section. Magnetic reed switches are tapped at

l-inch intervals along the resistor network. The

Sometimes you are only required to know if a level

exceeds or goes below a certain preset parameter.

reed switches are sequentially connected through

Other circumstances require that you know the

series resistors to a common conductor. This net-

work is enclosed in a stem that is mounted ver-

exact level. If only a predetermined limit is

needed, you can use a float switch. This will make

tically in the tank. A float containing bar magnets

contact when the set point is reached and will

rides up and down the stem as the level changes.

sound an alarm. If you need to know a specific

In many tanks, you have to use more than one

level, then you must use a variable sensing device.

transmitter section to measure the full range. The

Figure 5-22.--Typical setup fur calibrating a pressure device.

5-17