Many differential pressure gauges are of the

conjunction with signal conditioners. Transducers

bellows type. In some designs, one pressure is

provide the capability of sensing variable pressures

applied to the inside of the bellows and the other

and transmitting them in proportional electrical

pressure is applied to the outside. In other designs,

signals. Pressure transducers, like pressure

a differential pressure reading is obtained by

switches, are widely used in ship propulsion and

opposing two bellows in a single case.

auxiliary machinery spaces. They are used to

Bellows elements are used in various applica-

monitor alarms and in machinery operation.

tions where the pressure-sensitive device must be

powerful enough to operate not only the in-

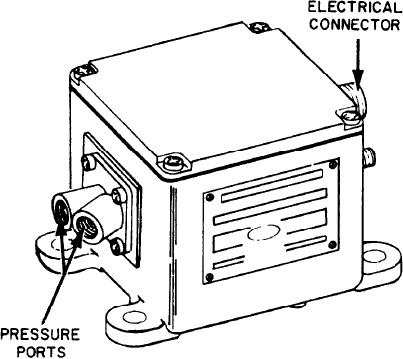

Pressure Transducer Operation

dicating pointer but also some type of recording

device.

Pressure transducers are generally designed to

sense absolute, gauge, or differential pressure.

ELECTRICAL PRESSURE MEASURING

The typical unit (fig. 5-18) receives pressure

INSTRUMENTS (TRANSDUCERS)

through the pressure ports. It transmits an

electrical signal, proportional to the pressure

Transducers are devices that receive energy

input, through the electrical connector. Pressure

from one system and retransmit it to another

transducers are available in pressure ranges from

system. The energy retransmitted is often in a

0 to 6 inches water differential to 0 to 10,000 psig.

different form than that received. In this section,

Regardless of the pressure range of a specific unit,

we will discuss the pressure transducer. This device

the electrical output is always the same. The

receives energy in the form of pressure and

electrical signal is conditioned by the signal

retransmits energy in the form of electrical

conditioners before being displayed on an analog

current.

meter or a digital readout located on one of the

Transducers allow monitoring at remote

control consoles.

locations on gas turbine propulsion plants.

Mechanical gauges provide pressure readings at

Pressure Transducer Calibration

the machinery locations or on gauge panels in the

immediate area. At a central location remote

Pressure transducers should be calibrated on

readings are provided by using transducers in

a bench before installation. The equipment needed

Figure 5-18.--Pressure transducer assembly.

5-13