possible to get wider variation in differential

settings.

Adjustments

To set the operating range of the switch, turn

the differential adjustment screw (fig. 5-11)

counterclockwise against the stop for minimum

differential. Bring the temperature to the value

at which the circuit is to be closed. If the switch

contacts are open at this temperature, turn the

range screw slowly clockwise until the contacts

close. If the contacts are closed when the desired

temperature is reached, turn the range screw

counterclockwise until the contacts open; then

turn the screw slowly clockwise until the contacts

close. These adjustments set the closing

temperature.

The temperature is now raised to the point

where the circuit is to be opened. Since the

differential adjustment is now set at minimum,

the circuit will probably open at a lower

temperature than desired; therefore, turn the

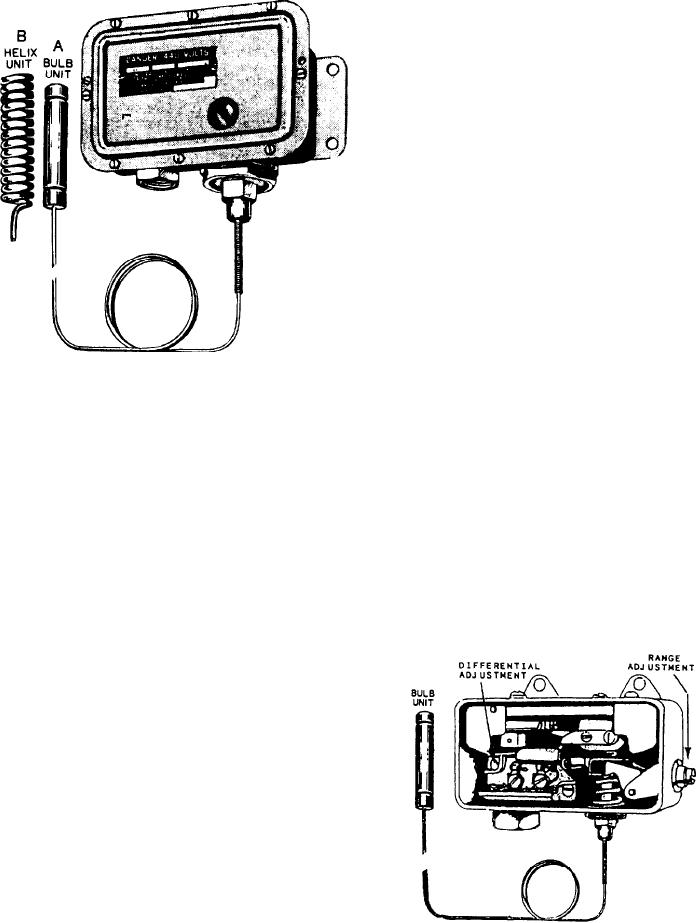

Figure 5-10.--Temperature switch with two types of

differential adjustment screw clockwise to widen

sensing elements. A . Bulb unit. B. Helix unit.

the differential until the desired opening

temperature is obtained. For further instructions

on how to adjust these switches, refer to the

control circuits. For the thermal unit to be most

manufacturers' technical manuals.

effective, it must be located at a point of

unrestricted circulation. This is so it can "feel"

the average temperature of the substance you wish

PRESSURE MEASURING

to control.

INSTRUMENTS

Temperature changes cause a change in the

Pressure, like temperature, is one of the basic

volume of the sealed-in gas, which causes move-

engineering measurements and one that must be

m e n t of a diaphragm. The movement is

transmitted by a plunger to the switch arm. The

moving contact is on the arm. A fixed contact may

be arranged so the switch will open or close on

a temperature rise. This allows the switch contacts

to be arranged to close when the temperature

drops to a predetermined value and to open when

the temperature rises to the desired value. The

reverse action can be obtained by a change in the

contact positions.

The difference in temperature for the contact

opening set point and closing set point is the

differential. The switch mechanism has a built-in

differential adjustment so the differential can

be varied over a small range. Once set, the

differential remains essentially constant at all

temperature settings.

Some switches are stamped WIDE DIF-

FERENTIAL. These switches are adjusted in the

same manner described for the regular controls.

However, because of slight design changes, it is

Figure 5-11.--Temperature switch.

5-9