panels in the immediate area. To provide remote

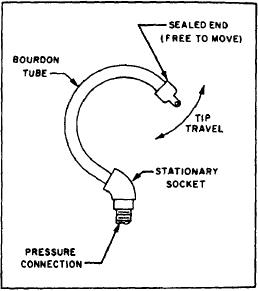

at the other (fig. 5-5). The open end of the tube

indications at a central location, you use electrical

is fixed in position, and the sealed end is free to

temperature measuring devices in conjunction

move. The tube is more or less elliptical in cross

with signal conditioners. The devices we will

section; it does not form a true circle. It

discuss in this section are the resistance

becomes less circular when there is an increase

temperature detectors (RTDs), the resistance

in the volume or in the internal pressure of the

temperature elements (RTEs), and thermocouples.

contained fluid; this tends to straighten the tube.

These devices sense variable temperatures at a

Opposing this action, the spring action of the tube

given point in the system and transmit the signals

metal tends to coil the tube. Since the open end

to a remotely located indicator.

of the Bourdon tube is rigidly fastened, the sealed

end moves as the volume or pressure of the

Resistance Temperature Detectors

contained fluid changes. A pointer is attached to

the sealed end of the tube through appropriate

The RTDs operate on the principle that

linkages; the assembly is placed over an

electrical resistance changes in a predictable

appropriately calibrated dial. The result is a

manner with temperature changes. The elements

Bourdon-tube gauge that may be used for

of RTDs are made of nickel, copper, or platinum.

measuring temperature or pressure, depending

Nickel and copper are used for temperatures of

upon the design of the gauge and the calibration

600F or lower. Platinum elements are used for

of the scale.

temperatures of 600F or greater. Figure 5-6

Bourdon tubes are made in several shapes for

shows two typical types of RTDs.

various applications. The C-shaped Bourdon tube

As with the bimetallic thermometers, you will

shown in figure 5-5 is perhaps the most commonly

usually find RTDs mounted in thermowells.

used type; spiral and helical Bourdon tubes are

Thermowells protect sensors from physical

used where design requirements include the need

damage by keeping them isolated from the

for a longer length Bourdon tube.

medium being measured. This arrangement also

lets you change the RTD without securing the

ELECTRICAL TEMPERATURE

system in which it is mounted. This makes your

MEASURING DEVICES

maintenance easier and less messy.

As temperature increases around an RTD, the

On the gas turbine propulsion plant, you will

corresponding resistance will also increase at a

have to monitor temperature readings at remote

proportional value. The temperature applied to

locations. Expansion thermometers provide

an RTD, if known, will give you a known

indications at the machinery locations or on gauge

resistance value. You can find these resistance

values listed in tables in the manufacturers'

technical manuals. Normally, only a few

resistance values are given.

To test an RTD, you will have to heat it to

a specific temperature. At this temperature the

resistance of the RTD should be at the resistance

shown in the table. The most common method

of heating an RTD is to use a pan of hot water

and a calibrated thermometer. Some newer ships

and repair activities test RTDs using a thermobulb

tester. This method is more accurate and easier

to use. For specific instructions, refer to the

manufacturers' technical manuals supplied with

the equipment.

The most common fault you will find with an

RTD will be either a short circuit or an open

circuit. You can quickly diagnose these faults by

using digital display readings or data log print-

outs. By observing the reading or the printout,

you may find that the indication is either zero or

a very low value. A malfunction of this type

Figure 5-5.--C-shaped Bourdon tube.

5-4