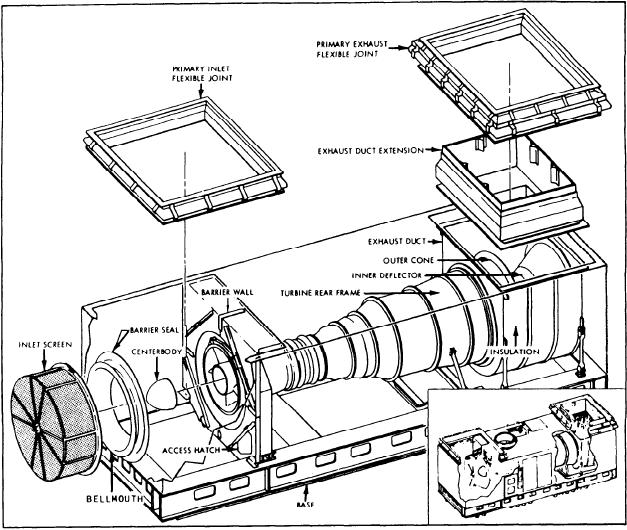

Figure 2-11.--GTE air inlet and exhaust.

4. An inlet duct, which is bell-shaped and

Figure 2-11 shows the air inlet and exhaust

attached to the front frame of the compressor.

components of a GTE. We will discuss the exhaust

The duct, or bellmouth, smoothes the airflow

system after we describe the intake system.

entering the turbine. A flexible seal is attached

between the inlet duct and the barrier wall.

The intake section of the enclosure is

composed of five parts:

5. A dome-shaped faring, called the center-

body, which is attached to the compressor front

1. A primary inlet flexible joint, which

frame hub to aid in smoothing the airflow.

connects the ship's ducting with the enclosure. It

has an upper and lower flange and a fiber-filled

flexible boot.

CG, DD, AND INLET

2. A barrier wall, which has four stainless steel

DUCT SYSTEMS

panels bolted together. It prevents exhaust and

ventilation air from being drawn into the intake.

The inlet duct systems for the CG-, DD-

It has a removable access hatch for maintenance/

c l a s s ships are very similar. The major

operator personnel access to the inlet plenum.

difference is the sand separators used on the

3. A wire mesh inlet screen (foreign object

ships. Since only the four 993

damage (FOD) screen), which is bolted to the

class ships have the sand separators installed, we

barrier wall and prevents foreign objects from

will not discuss this unique feature.

entering the engine.

2-10