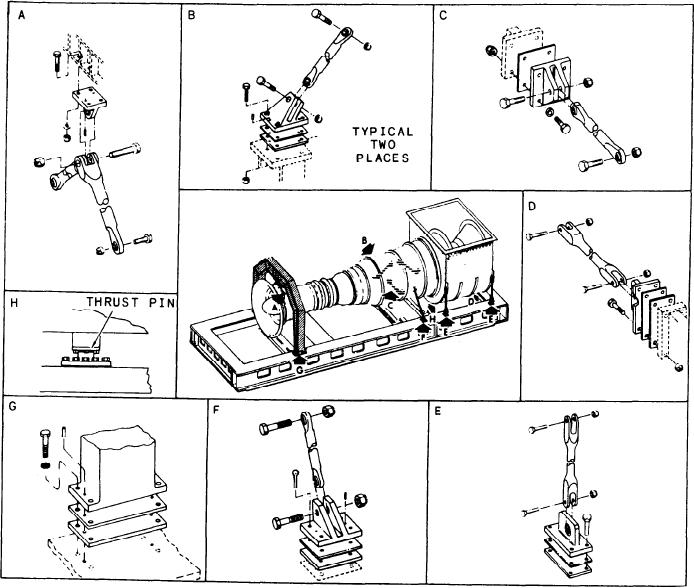

Figure 2-5.--Gas turbine assembly mounting.

positions apply when viewing the GTE from the

explosionproof and fireproof. The inner wall is

rear (exhaust end) looking forward.

constructed of perforated metal and can withstand

a temperature of 2000F for 15 minutes.) With

ventilation air being supplied to the enclosure, the

ENCLOSURE

temperature of the outer wall normally does not

exceed 150F. The right and left propulsion GTE

Refer to figure 2-3 as we discuss the enclosure.

modules are functionally identical. The only

It is a soundproof, fire-resistant housing in which

difference between the enclosures of the different

the GTE operates. The enclosure provides

class ships is their access to the engine.

thermal and acoustical insulation, inlet and

exhaust ducting, and a controlled environment for

the GTE. Flexible coupling joints are provided at

Lighting

the air inlet and exhaust ducts which allow a flow

path/interface between the enclosure and the

Enclosure illumination is provided by nine

ship's ducting. The enclosure is of double-wall

explosionproof light fixtures--eight on the

construction. (NOTE: For personnel safety,

ceiling and one on the base. With the exception

testing was conducted to ensure the enclosure is

o f the CGs module illumination is the

2-5