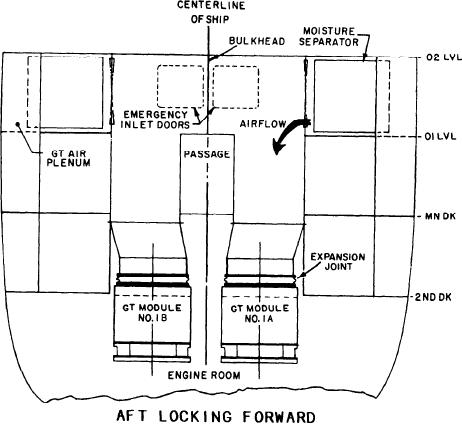

Figure 2-14.--FFG air intake system.

duct. The permanently installed rails extend

Besides the ducting, the GTE uptake and

through the high hat section. These serve to guide

intake system includes moisture separator

the engine as it is lifted vertically from the ship.

assemblies, emergency inlet doors, and cooling air

Removal of the engine is accomplished in two

fans (not shown). Also included are cooling air

operations due to space constraints. The GG is

bypass dampers and provisions for anti-icing

separated from the PT while still in the enclosure.

upstream and downstream of the moisture

Then it is removed from the ship, followed by

separators (not shown).

removal of the PT.

Demister Panels

The demister panels (or moisture separators)

FFG INLET DUCT SYSTEM

are of knit wire mesh construction mounted in a

Refer to figure 2-14 as we discuss the FFG

supporting frame. They remove moisture droplets

inlet duct system. The GTE uptake spaces and

containing sea salt and prevent other foreign

objects from entering the intake and cooling air

intake system house three separate ducting systems

per GTE. They are for combustion air, module

ducts. In operation, the moisture droplets adhere

cooling air, and exhaust gas elimination.

to the wire mesh while the air passes through. The

Atmospheric air for the combustion and cooling

moisture droplets coalesce into larger drops and

air ducting normally enters through the intake

fall free of the airstream. They then drain into

plenums. These are located on each side of the

troughs which are piped to the plumbing drains

ship's structure. The air is then carried through

system. Each combustion air intake duct has eight

ducting to the GTMs in the engine room below.

demister panels. Each cooling air intake duct has

Ducting connections to the GTMs are made via

four panels.

expansion joints on top of each GTM. The

Blow-In Doors

combustion air intake ducts also provide the

access for removal and replacement of the engine

Emergency inlet (blow-in) doors are provided

GG and PT sections.

in the combustion air and cooling air ducts to each

2-13