external manifold. From the manifold, the air is

Ignition Leads

piped forward and aft to ejector nozzles. Each

The ignition leads are low-loss connections

ejector contains a venturi through which the

between the ignition exciters and the spark

eighth-stage air passes; it draws enclosure air

igniters. They are coaxial leads with metallic

into the ejector. This air mixes with the eighth-

shielding that incorporates copper inner braid,

stage air, reduces the downstream pressure and

sealed flexible conduit, and nickel outer braid.

temperature, and increases the volume. Air from

the forward ejector is piped into the front frame

WATER WASH SYSTEM

hub; there it pressurizes and cools the A sump.

Some of the A-sump air passes through holes in

The purpose of the water wash system is to

the compressor rotor front shaft, through the

remove contaminants from the inlet and com-

rotor air duct, and through holes in the rotor aft

pressor sections. The system has a water

shaft; there it pressurizes and cools the B sump.

wash/rinse supply tank and piping attached to the

Air from the rear ejector is piped into the turbine

outside of the base enclosure. A flexible hose is

rear frame hub; it is used to pressurize and cool

attached from the inside base enclosure floor to

the D sump. Part of the air entering the D sump

the GG inlet duct at the 6 o'clock position. The

bleeds into the flexible-coupling shaft tunnel for

inlet duct is made with an internal passageway or

cooling and passes out the aft end of the exhaust

manifold which distributes water wash fluid to

duct. Some of the D-sump air passes through

outlet spray orifices. The outlet spray orifices eject

holes in the PT aft shaft, rotor air tube, and holes

the water wash fluid into the airstream flowing

in the rotor front shaft; there it pressurizes and

through the inlet duct.

cools the C sump.

BLEED AIR SYSTEM

Ninth-Stage Air

Air extracted from the compressor for cooling,

seal pressurization, pressure balance to reduce

Ninth-stage air is bled from the compressor

rotor thrust loads, and ship's service (secondary)

through holes in the ninth-stage vane bases and

air is called bleed air. For this application, air is

compressor casing into an external manifold.

bled from the 8th, 9th, 13th, and 16th stages. Only

There it is piped to the turbine mid frame and

16th-stage air (known as CDP) is used for the

turbine rear frame. Air enters the turbine mid

ship's bleed air system. Refer to figure 1-33

frame through all the struts. Some of the air

(At the end of chapter 1), which shows the

exits through holes in the frame hub to cool the

LM2500 GTE airflow, to help you understand the

frame inner liner. The rest of the air enters tubes

following discussion.

in the C-sump air seals; after it crosses these seals,

the air passes through and cools the PT rotor. It

Eighth-Stage Air

then exits into the PT exhaust gas. The air to the

turbine rear frame enters the frame through struts

Eighth-stage air is bled from the compressor

2 and 8. It passes into an area between the

through hollow eighth-stage stator vanes into an

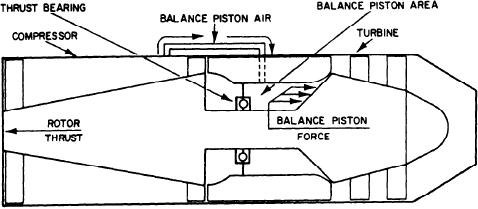

Figure 2-52.--Balance piston principle.

2-46