signal when the oil level is too high or too low.

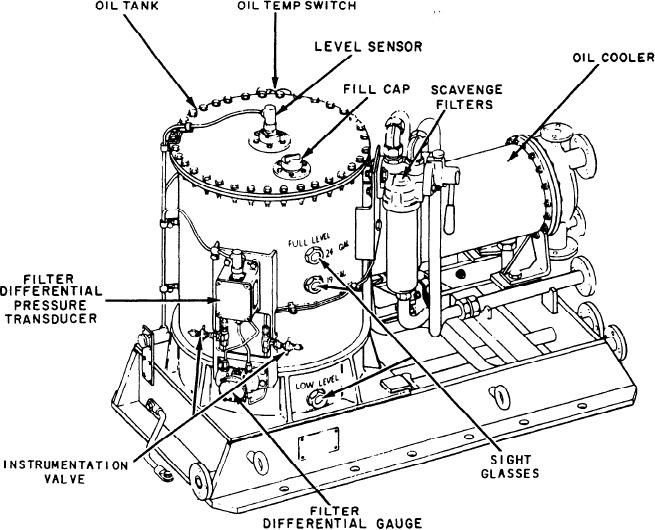

Lube Oil System Components

An oil level sensor on the FFG-class ship monitors

oil level from within the tank and transmits a

In this section we will describe the lube oil

continuous electrical signal for remote readout

system components in the order of lube oil flow,

of lube oil level. The oil tank is considered

from the LOSCA through the system and back

full when oil is visible at the 24-gallon sight

to the LOSCA.

glass.

Instrumentation valves, a filter differential

OIL TANK.--The oil tank is an integral

pressure transducer, a filter differential pressure

part of the LOSCA. The early configuration of

gauge, a level sensor, and an oil temperature

cast construction on the DD-class ship contains

switch are mounted on the tank. A gravity fill cap

six sight glasses (view ports) for visual detection

is installed on the tank cover fill port. The fill port

of oil level in the tank. Starting with the

has a strainer to prevent foreign material from

second glass from the bottom, they are spaced

entering the tank. Baffles are located in the

at 5-gallon intervals. On the later configuration

bottom of the tank to minimize oil sloshing. A

of fabricated construction (fig. 2-47), three

deaerator is inside the tank at the scavenge inlet

sight glasses are provided for low level, 19-gallon

(which separates air from the scavenge oil). You

level, and full level positions. An oil level

can drain the oil tank by positioning a lever

switch on the DD-class ship monitors oil level

located in the assembly base.

from within the tank and transmits an electrical

Figure 2-47.--LOSCA.

2-41