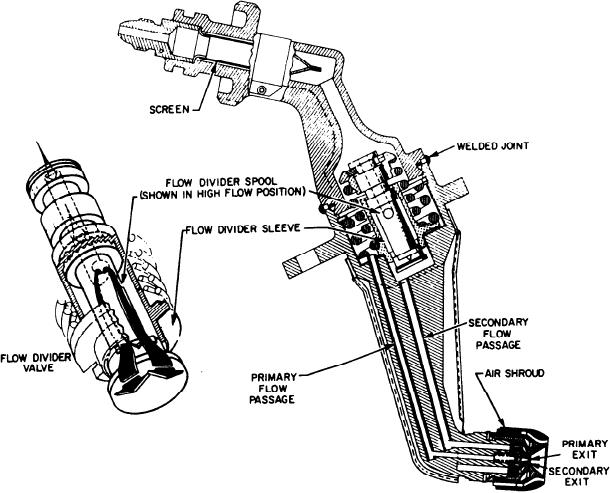

Figure 2-44.--Fuel nozzle.

Compressor Inlet Temperature Sensor

(fig. 2-44) is a dual-orifice, swirl atomizer

with an internal flow divider. The fuel nozzles

The CIT sensor has a constant-volume, gas-

produce the desired spray pattern over the full

filled probe and a metering valve. This sensor

range of fuel flow. Fuel enters the nozzle

controls or meters fuel across an orifice. It is

through a single tube, flows through a 117-micron

mounted at the 8 o'clock position in the

screen, and then the flow divider. When the

compressor front frame. The sensing probe

nozzle is pressurized, primary fuel flows through

projects through the frame into the airstream.

a drilled passage and tube assembly in the

Since the temperature sensing probe has a

nozzle shank. It then flows through the primary

constant volume, the gas pressure inside the

spin chamber and into the combustor. When

probe is equal to the temperature. This pressure

fuel pressure to the nozzle rises to 330 to 350 psig,

is connected to a sensing bellows, which, in

the flow divider opens and introduces secondary

turn, is connected to the metering valve. Fuel

fuel flow. The secondary fuel flows through

from the MFC enters the CIT sensor. There it is

the flow divider, through a passage in the

metered by the metering valve proportional to the

nozzle shank, into the secondary spin chamber,

temperature at the sensing probe. It is then used

and mixes with the primary flow as it enters

as a scheduling parameter by the MFC.

the combustor. An air shroud (swirl cup)

around the nozzle tip scoops a small quantity of

Variable Stator Vanes

air from the main airstream to cool the nozzle

The VSVs are positioned by two hydraulic

tip. This retards the buildup of carbon deposits

actuators operated by fuel pressure from the

on its face.

2-38