position; it adjusts the fuel flow to maintain the

desired speed set by the power lever. The MFC

is a hydromechanical device which operates by use

of fuel-operated servo valves. The MFC has two

primary functions. One is to control GG speed

(schedules acceleration fuel flow and deceleration

fuel flow). The other controls stator vane angle

(for stall-free, optimum performance over the

operating range of the GTE).

The MFC controls GG speed as a function of

power lever position. The power level is set

electrically by a signal from the FSEE. Movement

of the power lever changes speed demand. A

flyweight governor senses GG speed. This adjusts

the fuel flow as necessary to maintain the speed

set by the power lever. Three fuel schedules

are established by the control: acceleration,

deceleration, and minimum fuel schedules. The

acceleration schedule limits fuel flow necessary

for acceleration to prevent overtemperature and

stall. The deceleration schedule limits the rate of

fuel flow decrease to prevent combustion

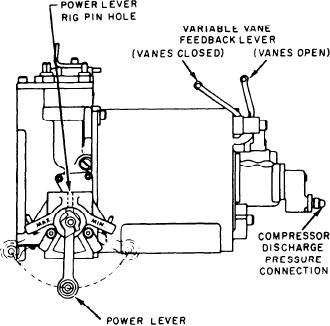

Figure 2-42.--Main fuel control.

flameout during deceleration. The minimum fuel

schedule limits fuel flow for starting to prevent

per square inch absolute (psia); it reseats at or

overtemperature. The MFC senses CIT, CDP,

above 1,325 psia. These features protect the pump

and NGG, which biases the fuel schedules as a

function of atmospheric and engine operating

and downstream components against excessive

conditions.

system pressures.

The MFC schedules the VSVs as a function

The fuel filter (5) is an HP filter mounted on

of GG speed and CIT. Actual position of the

the fuel pump and flange-ported to eliminate

VSVs is sensed by the control via a position

external piping. The head houses a bypass relief

feedback cable. One end of the feedback cable

valve (6); the bowl houses the filter element. The

is connected to the left master lever arm. The

filter element is rated at 46 microns nominal

other end is connected to the feedback lever on

and 74 microns absolute. It prevents larger

the MFC.

contaminants from being carried into the MFC.

High-pressure fuel flows from the fuel pump

through the flange port and enters the filter bowl.

Pressurizing Valve

The fuel then flows from the outside of the filter

element to the center, up into the head, out the

The pressurizing valve pressurizes the fuel

flange return port, and back into the fuel pump.

system. It ensures adequate fuel control servo

There, it is routed to the MFC. If the filter

supply pressure and VSV actuation pressure.

becomes clogged, the bypass relief valve opens at

These pressures are essential for proper fuel and

35 pounds per square inch differential (psid).

stator vane scheduling during GG operation at low

From the MFC the fuel goes to the fuel shutdown

fuel flow levels. The valve is a fuel pressure-

valves, the purge valve, the fuel manifold, and

operated, piston-type valve. The piston is held on

finally the fuel nozzles.

its seat (closed) by spring force and fuel pressure

(reference pressure) from the MFC. Servo

pressure is 110 to 275 psig. The MFC discharge

Main Fuel Control

fuel (metered fuel for combustion) enters the

pressurizing valve at the opposite side of the

The MFC (fig. 2-42) is basically a speed

piston. When MFC discharge pressure is 80 to 130

governor which senses NGG and power lever

2-36