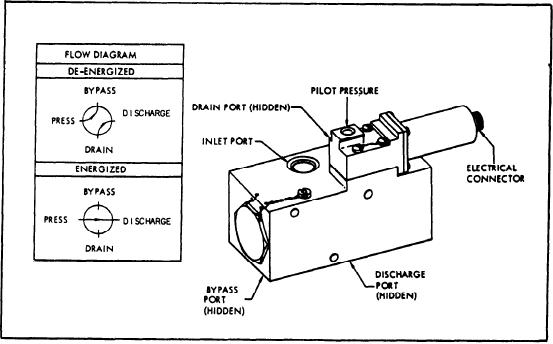

Figure 2-43.--Fuel shutdown valve.

psig greater than reference pressure, the valve

backflow into the No. 2 valve from the No. 1

opens. The upstream pressure (including servo

valve bypass line.

supply and stator actuation) is 190 psig or greater

before the pressurizing valve opens. This is

Purge Valve

adequate for proper operation.

The purge valve operates electrically. It is a

normally-closed, on-off valve used to drain low-

Fuel Shutdown Valves

temperature fuel from the system before a GTE

start. It is spring-loaded to the closed position;

The two fuel shutdown valves (fig. 2-43) are

a solenoid opens the valve when it is energized.

pilot-valve actuated and electrically controlled.

About 3 gallons of fuel are drained from the

The valves are piped hydraulically in series. They

system during purging.

are electrically operated in parallel by control logic

during an automatic sequence. The console

Fuel Manifold System

operator can also operate them at the LOP, the

PCC, or the PACC during a manual stop. Both

The fuel manifold system is shrouded. (The

valves must be energized to port metered fuel to

manifold and the manifold-to-fuel nozzle con-

nector tubes are tubes within a tube assembly.)

the GG fuel manifold. De-energizing either valve

If a fuel leak develops in the manifold system,

will bypass the fuel back to the pump inlet.

Normally, both valves are de-energized to shut

the leakage collects inside the shroud. It is then

down the engine. The second valve acts as a

drained through a drain line to a telltale drain

backup and will bypass fuel if the first should fail

under the enclosure base. Next it goes to a

to function. You can operate the two valves

collection tank. Fuel leakage inside the enclosure

from the manifold system is prevented and fire

independently from the LOP as a maintenance

check.

hazard is minimized by this system design.

Each shutdown valve has a pilot pressure bleed

relief valve to prevent backflow through the valve

Fuel Nozzles

during GTE motoring. A check valve which has

The LM2500 GTE uses 30 fuel nozzles to

a 2 psid cracking pressure is located in the bypass

port of the No. 2 shutdown valve to prevent fuel

admit fuel to the combustor. The fuel nozzle

2-37