MFC. The MFC has a variable vane scheduling,

forward flange at the 3 o'clock and 9 o'clock

3-dimensional (3-D) cam which is positioned by

positions. They are connected to the VSVs

NGG and CIT signals; it has a variable vane

through master lever arms and actuation rings.

feedback mechanism which receives a vane

The MFC schedules HP fuel to either the

position signal from a linkage connected to

head-end port (opens VSVs) or the rod-end

the VSV master lever; it also has a variable

port (closes VSVs). Control parameters sensed

vane pilot valve positioned as a result of the

by the MFC to schedule variable vane angle

comparison of the scheduling cam position

are NGG, CIT, and stator vane angle via a

feedback cable. The feedback cable is connected

and the feedback signal. Changes in engine

speed rotate the scheduling cam; changes in

on one end to the left master lever arm

CIT reposition the cam. Movement of the cam

and on the other end to the MFC.

repositions the pilot valve. The pilot valve

ports HP fuel (pump discharge pressure) to

Power Lever Angle Rotary Actuator

either the rod end (closing) or head end

(opening) of the vane actuators; it vents

the other end to bypass pressure. The variable

The PLA rotary actuator is an electro-

vane actuating linkage mechanically transmits

mechanical device that interfaces the PLA

actuator electronics in the FSEE with the MFC

the actuator movement to the variable vanes

of the GTE. It moves the internal components

and IGVs. A flexible cable is attached to the

linkage. It transmits a feedback signal to the

of the MFC to control fuel flow to the engine.

MFC. The feedback mechanism in the MFC

It has a dc servomotor, a reducing gear, a

repositions the pilot valve to terminate the

slide potentiometer, a tachometer generator,

actuator signal when the vanes reach the scheduled

mechanical linkage, and an electrical line filter.

position.

The PLA actuator is mounted on the fuel pump;

it is connected to the fuel control power lever

through a mechanical linkage. It is electrically

Variable Stator Vane Actuators

connected to the FSEE.

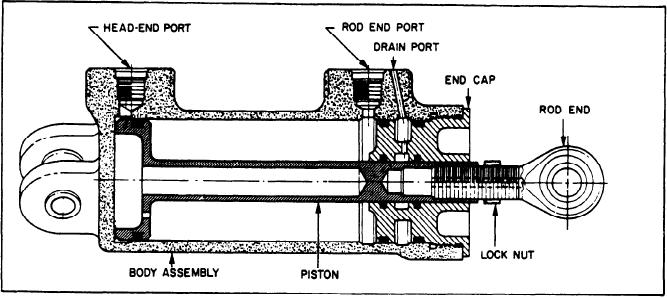

The VSV actuators (fig. 2-45) are single-ended,

Signals from the PLA actuator electronics,

located in the FSEE, are converted by a servo-

uncushioned hydraulic cylinders which are driven

in either direction by HP fuel. The piston stroke

mechanism into mechanical action that positions

is controlled by internal stops. The two actuators

the fuel-control power lever. Feedback of PLA

are mounted tangentially on the compressor stator

and rate of change are sent to the FSEE. A

Figure 2-45.--VSV actuator, cross-sectional view.

2-39