The turbine rotor has four wheels containing

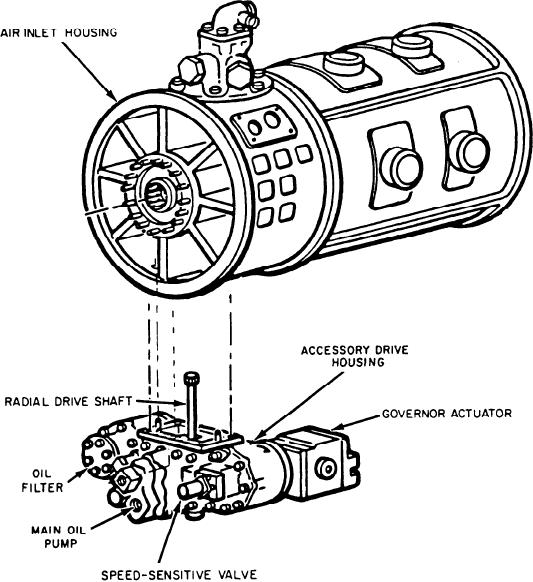

pump, governor actuator, and external scavenge

oil pump. Pads on the front face are for the speed-

the turbine blades and is supported at each end

sensitive valve, main oil pump, and oil filter (this

by roller bearings. The turbine rotor extracts

requires no gearing). The components themselves

energy from the hot exhaust gas. It converts this

are discussed later in this chapter. The accessory

energy into shaft horsepower to drive the com-

pressor through a coupling shaft that runs through

drive is driven by the compressor rotor extension

the combustion chamber inner casing liner as-

shaft. This is accomplished by bevel gears that

drive a radial drive shaft, located in the inlet hous-

sembly and the generator through the PTO shaft

ing. The radial drive shaft is splined into one bevel

and reduction gear. This is different from the

gear through the bottommost strut of the inlet

LM2500 GTE. It uses one turbine to drive its com-

housing. A pinion on the other end of the shaft

pressor and a separate turbine to drive its load.

drives the gears in the accessory drive housing.

ACCESSORY DRIVE SECTION

ENGINE SYSTEMS

The accessory drive housing (fig. 3-15) pro-

vides mounting pads on the front and rear faces.

As previously mentioned, the model 104 and

The pads on the rear face are for the fuel

the model 139 both use the same GTE. However,

Figure 3-15.--Allison 501-K17 accessory drive housing.

3-18