turbine inlet casing at the rear. The aft end of the

inner casing is bolted to the turbine inlet casing.

The front end is supported by a sleeve in the

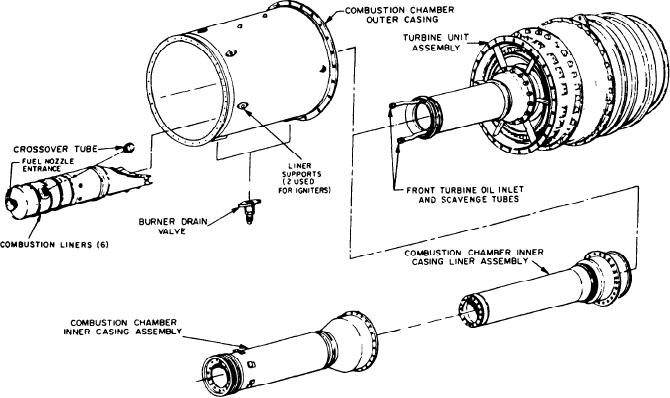

The combustion section has six individual

diffuser.

combustion chambers (burner cans) (fig. 3-13).

About 25 percent of the compressor discharge

They are equally spaced in an annulus formed by

air entering the combustion section passes to the

a one-piece outer casing and a two-piece inner

burner cans. Combustion takes place in the six

casing. Six crossover tubes connect the burner

cans. These provide flame dispersal during

combustion liners. Air initially enters the liners

through vanes at the front of the liners that swirl

starting. The burner cans are held by the fuel

the airflow. The swirling air mixes with the fuel

nozzles, spark igniters (two chambers), and liner

sprayed into the liners by the fuel nozzles. The

supports (four chambers). The burner cans are of

mixture is ignited during start by the spark igniters

welded construction.

located in two of the liners (these are described

The outer casing encloses the burner cans and

later in this chapter). After a start, a steady flame

provides the supporting structure between the

is established by the constant addition of fuel and

diffuser and turbine. The casing has two drain

air.

valves to drain unburned fuel after shutdown or

Holes along the body of the liners allow

after a false start. They may be called either

cooling air to enter the liners. This air provides

burner drain valves (model 104) or combustor

a buffer between the liner and the hot flames. Two

drain valves (model 139). These valves open when

reverse flow baffles ensure the liners direct air

combustion pressure drops below 1 to 5 psig. They

from some of the cooling air holes toward the

close above 2 to 5 psig on increasing pressure.

front of each liner. This cools the forward portion

The two-piece inner casing has an inner casing

of the liners and provides additional turbulence

and inner casing liner. These are separated by an

(for better combustion) of the fuel and air

air space and bolted together at the front. The

mixture. The hot gases produced in the liners exist

inner casing liner has a bellows to take up thermal

through a transition section into the turbine.

expansion and contraction. It is bolted to the

Figure 3-13.--Allision 501-K17 combustion section.

3-16