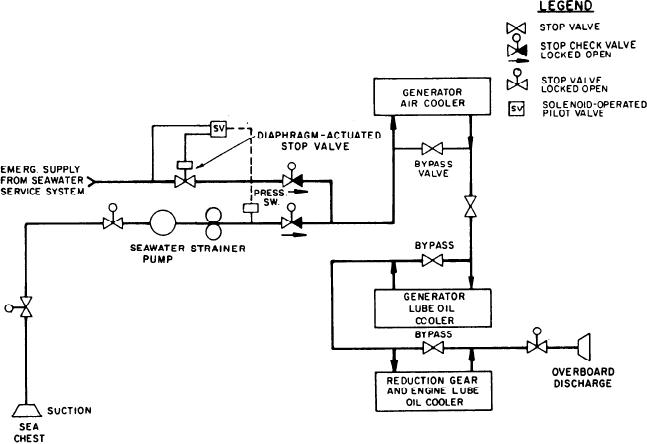

must be released manually at the bank. The

the three coolers. Therefore, each unit has a

bypass valve to adjust the amount of seawater

secondary system is not equipped with monitors

flowing through the cooler. This amount is

or alarms. Once released, CO2 discharge cannot

based on the temperature of the oil or air being

be stopped. The secondary discharge is at the rate

cooled.

of 67 lb/min.

If the electric pump system fails, emergency

cooling water is supplied by the ship's seawater

SEAWATER SERVICE SYSTEM

service system. This is accomplished by activation

of the pressure switch that senses pump discharge

Each GTGS has an independent seawater

pressure. If the GTGS is running and pump

service system for the lube oil coolers and

discharge pressure drops below the pressure switch

generator air cooler. Power for the pumps is taken

set point, the solenoid-operated pilot valve will

from the generator side of the main circuit

energize, opening the diaphragm-actuated stop

breaker. Thus, the electric pumps start automa-

valve and circulating the emergency seawater

tically as the generator's voltage exceeds excitation

supply through the coolers. Seawater is discharged

voltage. Figure 3-8 is a flow diagram of this service

system. A solenoid-operated pilot valve auto-

overboard through an emergency stop valve.

matically opens the diaphragm-actuated,

hydraulically operated stop valve when LP

GTE ASSEMBLY

contacts close in the pressure switch in the normal

service line. Cooling water is drawn from the sea

The Allison 501-K17 is a single-shaft, axial-

chest. It flows through a strainer and then the

f l o w GTE. It has a 14-stage axial-flow

generator air cooler and lube oil cooler. It passes

through the reduction gear/engine lube oil cooler.

compressor, a can-annular combustor, and a

4-stage axial-flow turbine directly coupled to the

The seawater flow requirements are different for

Figure 3-8.--Generator seawater service system.

3-11