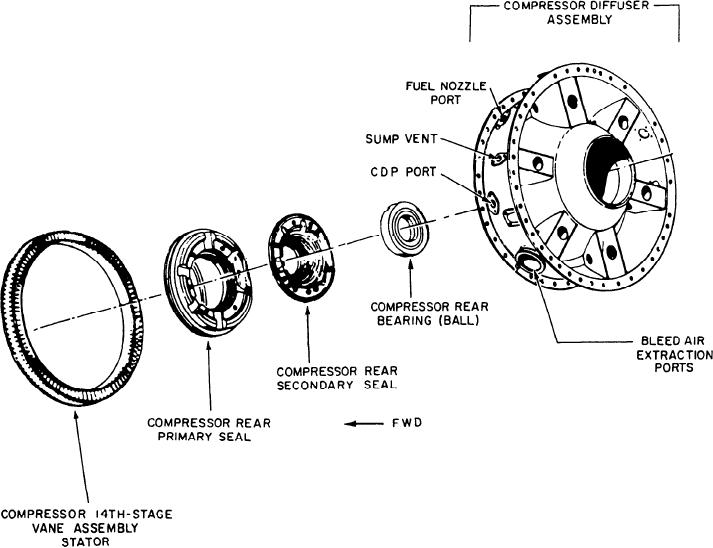

Figure 3-12.--Allison 501-K17 diffuser and 14th-stage stator vane assembly.

housing also has passages for directing anti-

guide vanes. The rotor is made up of 14 individual

icing air to the strut leading edges and the

wheels. The wheels contain the 14 stages of blades

IGV assembly. This assembly is located in

and are pressed and bolted together as one

the after side of the inlet housing. However,

assembly.

in this application, engine anti-icing is no longer

used.

The diffuser is of welded steel construction.

It is used to slow the compressor discharge air

before entering the combustor. The diffuser

COMPRESSOR SECTION

supports the compressor rear bearing/thrust

bearing, the compressor seal (two-stage)

The compressor section has a compressor

stationary members, and six fuel nozzles. It

stator (fig. 3-11, view A), a compressor rotor (fig.

provides three bleed air extraction ports to which

3-11, view B), and a diffuser (fig. 3-12). The air

a manifold is attached. This allows bleed air

inlet housing described in the preceding paragraph

extraction (up to 10 percent of total engine

is also part of the compressor section. The

airflow) to the ship's bleed air system. Bleed air

compressor case is made up of four sections bolted

is also extracted for use in keeping the 5th- and

togetber along horizontal split lines. The case

10th-stage bleed valves closed during normal

operation.

contains the 14 stages of stator vanes and the exit

3-15