after cleaning. Each filter chamber has a vent and

Lube Oil Filter

a drain.

The LO filter has two separate filter housings

The liftout filter elements are pleated wire

cloth, supported by inner and outer perforated

connected by interlocked inlet and outlet valves

metal tubes. Magnets, supported inside each filter

arranged so only one housing is in operation at

element, remove ferrous particles from the oil.

a time. Each filter housing contains 14 filter

elements rated at 65 microns. You can clean and

Header

reuse the filter elements. Each filter housing has

vent and drain connections. The filter is installed

Oil is supplied to the MRG and accessories by

in the piping downstream from the LO cooler to

the ship's main LO service system through a single

remove particulate matter from the LO. The filter

oil inlet LO header. The header has spray bar

has a single cast steel body mounted on a

assemblies equipped with spray nozzles to

fabricated steel base. The filter body contains two

lubricate all gear and pinion teeth. The spray

filter chambers and a diverting valve assembly.

nozzles are arranged to direct oil across the full.

The diverting valve connects the filter chambers

width of the teeth at the gear mesh. This properly

to the inlet and outlet ports. The filter chambers

lubricates tooth bearing surfaces and dissipates

are covered by bolted steel plates.

heat generated during operation.

A manually operated changeover assembly

Safety orifice plates are used for journal and

positions the diverting valve to place the right or

thrust bearings. The openings are sized to allow

left filter element in service. The selector lever is

sufficient lubrication under normal conditions but

positioned over the chamber selected. A hydraulic

to restrict excessive flow, such as that caused by

interlock prevents the shifting of oil flow to an

extreme bearing wear or bearing failure. These

open (nonpressurized) filter chamber. An inter-

orifice plates are installed in the flange joints

lock cylinder is connected to each of the filter

connecting the oil supply line to each bearing.

chambers. When a differential pressure exists

Orifice plugs are installed in the bearing seats for

between the chambers, the cylinders engage a

the high-speed pinions and input shafts.

notch in the diverting valve cam plate and

positively lock the selector lever. The changeover

SYSTEM MONITORING

assembly has a balancing valve that is used to

During operation, another one of your duties

equalize pressure between the chambers to allow

as watch stander is to monitor the LO system.

shifting. The assembly also fills the filter chamber

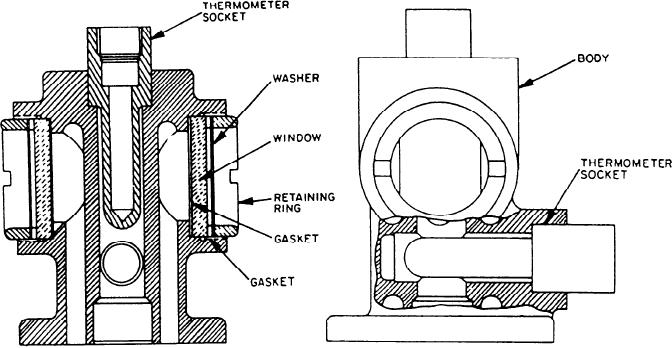

Figure 4-2.--Liquid sight indicator.

4-10