tanks. The FO in the service tanks can also be

recirculated through the purifier and back to the

service tanks by realigning the valves. The FO

must be circulated for a minimum of 3 hours

before a service tank is placed in operation. This

provides a means of continuously reducing the

amount of solid contaminants in the FO.

The CG-, and DD-class ships are

being furnished with self-cleaning centrifugal

purifiers (SCCPs). The purifier is a vertical, direct-

drive, centrifugal, self-cleaning (solids ejecting)

machine that has the capacity to purify 110 gpm

of contaminated diesel fuel, marine. The FO

contaminated with water and solids is fed into the

purifier. It separates the pure FO from the

contaminants and returns the purified FO to the

ship's FO system. The water is continuously

passed from the purifier through the ship's

piping to a waste oil tank. Separated solids in the

form of sludge are retained within the bowl

during the cycle. Cleaning the bowl during purifier

operation is referred to as "shooting" the bowl.

The ejected sludge is also passed to the waste oil

system. The purifier can remove water from a

contaminated mixture comprised of as much as

half water, half FO. Also, under emergency

conditions, the purifier can process 100% water for

a period of 5 minutes without any water discharge

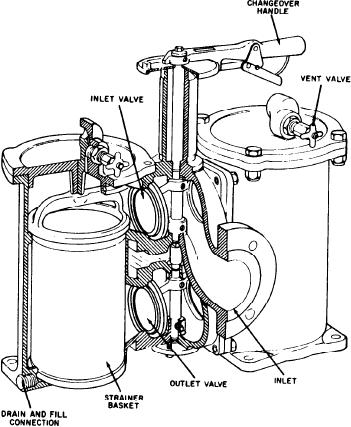

Figure 4-7.--Duplex FO strainer.

from the fuel discharge port.

Fuel Oil Service System

through the outlet. Duplex strainers contain two

separate strainer housings and baskets and a

The FO service tanks are similar to storage

changeover mechanism that is a shaft with inlet

tanks except they are not saltwater ballasted. The

and outlet valves attached to it. As the handle is

FO service tanks have the same type of liquid-level

moved, one set of valves opens and the other set

indicating system as other tanks aboard ship. The

closes, isolating one strainer assembly. The

major concern for the service tanks is cleanliness.

strainers have differential pressure gauges and

The FO service tanks must be maintained in a

alarm indicators to alert the operator when the

clean state of readiness. To maintain cleanliness,

strainer is dirty.

you must allow only clean FO to enter the

service tanks. The components of this system that

FUEL OIL BOOSTER PUMPS.--Each FO

we will discuss are the FO strainers, the FO heater,

service system has two booster pumps to provide

and the filter/coalescer.

the system pressure. The FO booster pump is a

vertical, screw-type, positive-displacement pump

FUEL OIL STRAINERS.--A wire-mesh

that is driven by a two-speed electric motor. This

basket strainer is normally installed between the

type of pump is found on the CG-, and DD-

service tank and the booster pump suction to filter

class ships. A sliding vane pump is used on

out large solid particles. Figure 4-7 is an example

the FFG-class ships. Directly following the pump

of a duplex FO strainer. Refer to volume 1,

discharge is a relief valve. Since the pump is

chapter 6, of NAVEDTRA 10563 for more

positive displacement, a relief valve is required to

detailed information on this type of strainer.

protect the system and the pump. The relief valve

The FO enters the top section of the strainer

bypasses FO back to the pump inlet.

body and is directed into one of the wire-mesh

baskets. Large, solid particles are trapped inside

FUEL OIL HEATER.--Fuel oil heaters are

the strainer basket, and clean FO travels on

installed in the service system after the FO booster

4-15